TRILUX – Automation is a necessity

Interview with a Logistic Expert

To shape the future of an industry, one must not only understand the framework conditions but also anticipate technological as well as societal trends. With the logistics company Raben Group, we have already realized several LED refurbishment projects in Poland, utilizing our E-LINE NEXT LED continuous line system, the light management system LIVELINK PREMIUM, and cloud services. We have taken advantage of this connection to ask some exciting questions about digitization in logistics to Michał Węgrzyn, Regional Contract Logistics Director at Raben Logistics Poland.

LOGISTICS IS CONSIDERED A DIGITAL FLAGSHIP INDUSTRY.

WHERE DOES YOUR COMPANY STAND CURRENTLY?

The Raben Group has been working for many years on the automation and robotization of processes and services. In automation, we focus on intelligent IT solutions, such as platforms that autonomously provide information for our customers, such as the estimated time of arrival (ETA) of a delivery. In the field of warehouse automation and robotics we implement devices for shipment tracking, utilize autonomous or semi-automatic forklifts, as well as collaborative robots with “cobotic” arms. Additionally, we incorporate sensors for the Internet of Things (IoT), VR driving simulators, and many other solutions that enhance the efficiency of warehouse and transport processes. The long-term goal is hyper-automation through the use of artificial intelligence, machine learning techniques, and the integration of information from other platforms and systems, such as IoT sensors, industrial CCTV cameras, or GPS systems.

WHAT ARE THE BENEFITS OF DIGITAL TOOLS FOR PLANNING LOGISTICS REAL ESTATE AND PROCESSES?

The digital simulation of warehouse processes helps us efficiently plan new warehouses or infrastructure expansions. We can review various workflows and models to identify where changes or improvements can be made. This allows us to virtually uncover bottlenecks and optimize positions and equipment – even before the first cent is invested and the first sod is turned.

We have also already implemented “digital twins,” which are digital models that fully replicate the real warehouse system and interact with it in real-time. Digital twins help to simulate various logistics scenarios, layouts, and process schematics virtually by showing how the real system reacts to changes.

IS AUTOMATION IN LOGISTICS A BLESSING OR A CURSE?

Against the backdrop of labor shortages and the complexity and diversity of tasks and processes in the logistics industry, automation is primarily a practical necessity. At Raben, we are currently focusing on Robotic Process Automation (RPA). RPA bots are not physical robots but software programs that can autonomously handle recurring, highly complex tasks, such as generating quotes and invoices, planning loading and unloading processes, calculating routes, and much more. RPA bots relieve employees by taking over tedious and error-prone routine tasks. And they perform their tasks much faster than their human counterparts, which helps alleviate labor shortages.

IN INDUSTRY 5.0, HUMAN WELL-BEING IS BECOMING INCREASINGLY IMPORTANT.

WHAT ROLE DOES LIGHTING PLAY IN THIS CONTEXT?

The days of poorly illuminated warehouses and logistics areas are definitely over. While lighting used to be primarily selected based on functional and normative criteria, factors such as light quality, human well-being, and health are now in the spotlight. The demands and expectations of employees regarding the attractiveness of their workplaces have increased enormously.

Well-designed lighting not only contributes to the well-being of employees but can also enhance efficiency at work. By reducing eye strain and creating a pleasant working environment, employees can work more attentively and productively, ultimately benefiting company performance.

IN THE LOGISTICS COMPLEX IN RUDA SLASKA YOU RELY ON SMART LIGHTING.

DOES IT PAY OFF?

Definitely, and in multiple ways. We chose 8 km of E-Line Next LED and the LiveLink light management system, particularly due to their high cost-effectiveness, light quality, and sustainability. Sensor technology for presence detection has also been integrated into the network for minimal energy consumption. However, light quality cannot be quantified in monetary terms. The luminaires in Ruda Slaska provide excellent visibility conditions throughout all hall areas with customized light distributions – from the floor up to a height of over 12 meters. This increases safety, visual comfort, and well-being alike.

AUTONOMOUS DELIVERY VEHICLES, DELIVERY ROBOTS, FLYING DRONES –

WHEN WILL WE SEE THESE APPROACHES IN PRACTICE?

All of these solutions have been around for some time. Their deployment is hindered not primarily by costs but mainly by regulatory requirements that do not always keep pace with technology. The safety of transportation and transported goods also plays an important role. Therefore, I think it will take some time before these solutions mentioned become prevalent in practice.

WHAT DOES THE FUTURE OF LOGISTICS LOOK LIKE FOR YOU?

The future belongs to ubiquitous artificial intelligence. Thanks to machine learning, robots will be able to evolve, make decisions autonomously, and carry out assigned tasks independently. Artificial intelligence will help optimize processes, reduce costs, and improve sustainability and efficiency. In the future, humans will probably only be the initiators and no longer the executors of the process in the supply chain. However, the role of the logistician will not disappear.

They will continue to support customers in realizing their business goals and plans. The only difference is that in the future, they may have access to a variety of digital solutions to optimize the delivery process to the end consumer. This means I don’t believe robots are a substitute for dedicated employees. Automation, robotics, or AI rather help them keep pace with the changing world.

SourceTRILUX

EMR Analysis

More information on TRILUX: See the full profile on EMR Executive Services

More information on Michael Huber (General Representative and Chairman of the Supervisory Board, TRILUX): See the full profile on EMR Executive Services

More information on Hubertus Volmert (Chairman of the Executive Board and Chief Executive Officer, TRILUX): See the full profile on EMR Executive Services

More information on Johannes Huxol (Chief Financial Officer, TRILUX): See the full profile on EMR Executive Services

More information on Joachim Geiger (Chief Sales Officer & Chief Marketing Officer, TRILUX): See the full profile on EMR Executive Services

More information on Sebastian Trägner (Chief Technology Officer, TRILUX): See the full profile on EMR Executive Services

More information on E-LINE NEXT LED by TRILUX: https://www.trilux.com/en/products/e-line-next-led/ + From experience. From the market. For the future.

The challenge

- different applications with different requirements

- integration of different modules

- compromises in planning, lighting quality and efficiency

The solution

- individually configurable LED trunking system

- groundbreaking light quality

- outstanding energy efficiency (up to 190 lm/W)

More information on LiveLink Light Management System by TRILUX: https://www.trilux.com/en/products/livelink-light-management/livelink/ + Intelligent lighting systems that are controlled via sensors, minimise their energy consumption, independently report maintenance needs and individually interact with users – the lighting market has changed enormously because of the LED transformation, increasing digitalisation and social mega-trends such as connectivity and big data.

This opens up diverse possibilities with the control and monitoring of lighting solutions. With light management that offers new functions via intelligence and that makes planning and installation highly simple. We have combined our expertise and specific experience with that of the sensor technology specialist STEINEL to develop this intelligent system: LiveLink.

More information on Sebastian Ludwig (Head of Competence Center Lighting Management, TRILUX): See the full profile on EMR Executive Services

More information on Claudia Lüdenbach (Application Manager Industry, TRILUX): See the full profile on EMR Executive Services

More information on Raben Group: https://www.raben-group.com/ + 15 European countries, 90 years of experience, around 1,300,000 m2 of warehousing space, over 160 locations – a truly impressive history and scale of operations. Still, Raben Group is not about numbers, but about people: an international team of over 12,000 employees, full of energy and passion for logistics, driven by similar ambitions and believing in the same values. We provide contract logistics services, domestic and international distribution, fresh logistics, sea and air forwarding and intermodal transport for customers operating in various branches. Everyday, we join them on the road, and we not only mean delivering the goods from point A to point B, but rather reaching long-term goals, building partnerships and positive relations. All this translates into a unique value that we share with our customers by creating and providing comprehensive and customised logistics solutions.

- 15 countries

- 160 +locations

- 1 300 000 m2 warehouse capacity

- 13 000 000 shipments annually

More information on Ewald Raben (Chief Executive Officer, Raben Group): https://www.raben-group.com/about-us/raben-group-in-europe + https://www.linkedin.com/in/ewald-raben-a0904514a/

More information on Michał Węgrzyn (Regional Contract Logistics Director, Raben Logistics Poland, Raben Group): N.A.

EMR Additional Notes:

- Distribution Center (DC) and Warehouses:

- A warehouse is used for storing products while a distribution center, apart from storing products offers value-added services like product mixing, order fulfillment, cross docking, packaging etc. A distribution center stores products for relatively lesser periods compared to a warehouse.

- Warehouses prioritize efficient storage and inventory management, while distribution centers focus on the timely and accurate movement of goods.

- WMS (Warehouse Management System):

- A warehouse management system (WMS) consists of software and processes that allow organizations to control and administer warehouse operations from the time goods or materials enter a warehouse until they move out.

- Warehouses sit at the center of manufacturing and supply chain operations because they hold all of the material used or produced in those processes, from raw materials to finished goods. The purpose of a WMS is to help ensure that goods and materials move through warehouses in the most efficient and cost-effective way. A WMS handles many functions that enable these movements, including inventory tracking, picking, receiving and putaway.

- A WMS also provides visibility into an organization’s inventory at any time and location, whether in a facility or in transit.

- The WMS knows where the required materials are stored and controls the supply and disposal of material as well as the transport between the production lines.

- Cobots (Collaborative Robots):

- A collaborative robot, also known as a cobot, is a robot that is capable of learning multiple tasks so it can assist human beings. In contrast, autonomous robots are hard-coded to repeatedly perform one task, work independently and remain stationary.

- Intended to work hand-in-hand with employees. These machines focus more on repetitive tasks, such as inspection and picking, to help workers focus more on tasks that require problem-solving skills.

- A robot is an autonomous machine that performs a task without human control. A cobot is an artificially intelligent robot that performs tasks in collaboration with human workers.

- According to ISO 10218 part 1 and part 2, there are four main types of collaborative robots: safety monitored stop, speed and separation, power and force limiting, and hand guiding.

- Autonomous Mobile Robot (AMR):

- Any robot that can understand and move through its environment without being overseen directly by an operator or on a fixed predetermined path. AMRs have an array of sophisticated sensors that enable them to understand and interpret their environment, which helps them to perform their task in the most efficient manner and path possible, navigating around fixed obstructions (building, racks, work stations, etc.) and variable obstructions (such as people, lift trucks, and debris). Though similar in many ways to automated guided vehicles (AGVs), AMRs differ in a number of important ways. The greatest of these differences is flexibility: AGVs must follow much more rigid, preset routes than AMRs. Autonomous mobile robots find the most efficient route to achieve each task, and are designed to work collaboratively with operators such as picking and sortation operations, whereas AGVs typically do not.

- Automated Guided Vehicles (AGV):

- An AGV system, or automated guided vehicle system, otherwise known as an automatic guided vehicle, autonomous guided vehicle or even automatic guided cart, is a system which follows a predestined path around a facility.

- Three types of AGVs are towing, fork trucks, and heavy load carriers. Each is designed to perform repetitive actions such as delivering raw materials, keep loads stable, and complete simple tasks.

- The main difference between an AGV and an AMR is that AMRs use free navigation by means of lasers, while AGVs are located with fixed elements: magnetic tapes, magnets, beacons, etc. So, to be effective, they must have a predictable route.

- Autonomous Case-handling Robots (ACR):

- Autonomous Case-handling Robot (ACR) systems are highly efficient “Goods to Person” solutions designed for totes & cartons transportation and process optimization, providing efficient, intelligent, flexible, and cost-effective warehouse automation solutions through robotics technology.

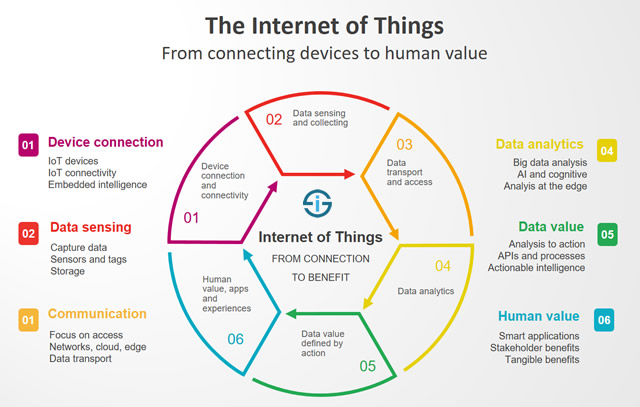

- IoT (Internet of Things):

- The Internet of Things (IoT) refers to a system of interrelated, internet-connected objects that are able to collect and transfer data over a wireless network without human intervention.

- Describes the network of physical objects—“things”—that are embedded with sensors, software, and other technologies for the purpose of connecting and exchanging data with other devices and systems over the internet.

- The Most Popular IoT Devices are:

- Smart watches are the most popular IoT devices. …

- Gaming consoles. …

- Smart TV sets and content streaming devices. …

- Voice control devices. …

- Printers. …

- Cameras. …

- Lighting appliances. …

- Smart thermostats.

- IIoT (Industrial IoT):

- Industrial IoT (IIoT) involves collecting and analyzing sensor-generated data to support equipment monitoring and maintenance, production process analytics and control, and more. In manufacturing IT since 1989, ScienceSoft offers IIoT consulting and development to create secure IIoT solutions.

- xIoT (xTended Internet of Things):

- xIoT refers to the “xTended” Internet of Things. This xTended IoT category spans Enterprise IoT devices (cameras, printers, and door controllers), OT devices (like PLCs, HMI’s, and robotics) and Network devices (like switches, WiFi routers, and NAS).

- VR/AR/ER (Virtual Reality/Augmented Reality/Extended Reality):

- Augmented reality (AR) adds digital elements to a live view often by using the camera on a smartphone. Examples of augmented reality experiences include Snapchat lenses and the game Pokemon Go. Virtual reality (VR) implies a complete immersion experience that shuts out the physical world.

- AR uses a real-world setting while VR is completely virtual. AR users can control their presence in the real world; VR users are controlled by the system. VR requires a headset device, but AR can be accessed with a smartphone. AR enhances both the virtual and real world while VR only enhances a fictional reality.

- Extended Reality (XR) is an umbrella term encapsulating Augmented Reality (AR), Virtual Reality (VR), Mixed Reality (MR), and everything in between. Although AR and VR offer a wide range of revolutionary experiences, the same underlying technologies are powering XR.

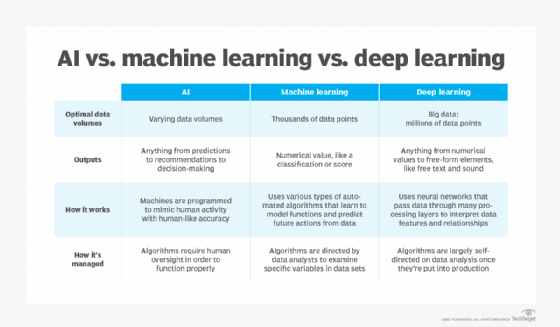

- AI – Artificial Intelligence:

- https://searchenterpriseai.techtarget.com/definition/AI-Artificial-Intelligence +

- Artificial intelligence is the simulation of human intelligence processes by machines, especially computer systems.

- As the hype around AI has accelerated, vendors have been scrambling to promote how their products and services use AI. Often what they refer to as AI is simply one component of AI, such as machine learning. AI requires a foundation of specialized hardware and software for writing and training machine learning algorithms. No one programming language is synonymous with AI, but well a few, including Python, R and Java, are popular.

- In general, AI systems work by ingesting large amounts of labeled training data, analyzing the data for correlations and patterns, and using these patterns to make predictions about future states. In this way, a chatbot that is fed examples of text chats can learn to produce lifelike exchanges with people, or an image recognition tool can learn to identify and describe objects in images by reviewing millions of examples.

- AI programming focuses on three cognitive skills: learning, reasoning and self-correction.

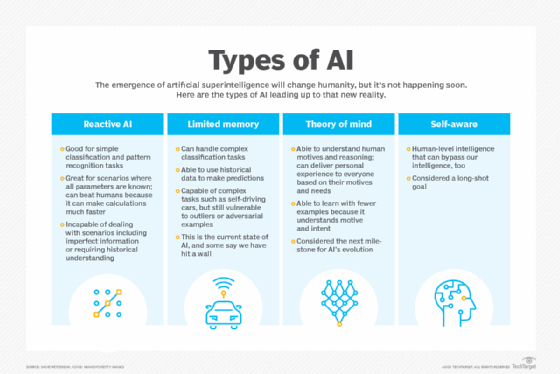

- What are the 4 types of artificial intelligence?

- Type 1: Reactive machines. These AI systems have no memory and are task specific. An example is Deep Blue, the IBM chess program that beat Garry Kasparov in the 1990s. Deep Blue can identify pieces on the chessboard and make predictions, but because it has no memory, it cannot use past experiences to inform future ones.

- Type 2: Limited memory. These AI systems have memory, so they can use past experiences to inform future decisions. Some of the decision-making functions in self-driving cars are designed this way.

- Type 3: Theory of mind. Theory of mind is a psychology term. When applied to AI, it means that the system would have the social intelligence to understand emotions. This type of AI will be able to infer human intentions and predict behavior, a necessary skill for AI systems to become integral members of human teams.

- Type 4: Self-awareness. In this category, AI systems have a sense of self, which gives them consciousness. Machines with self-awareness understand their own current state. This type of AI does not yet exist.

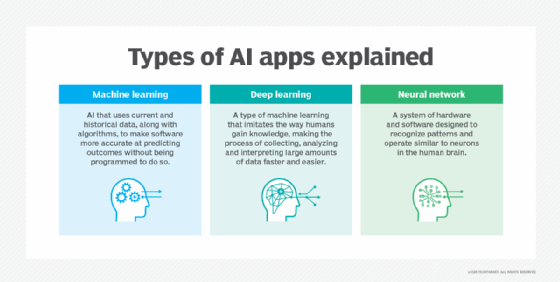

- Machine Learning (ML):

- Developed to mimic human intelligence, it lets the machines learn independently by ingesting vast amounts of data, statistics formulas and detecting patterns.

- ML allows software applications to become more accurate at predicting outcomes without being explicitly programmed to do so.

- ML algorithms use historical data as input to predict new output values.

- Recommendation engines are a common use case for ML. Other uses include fraud detection, spam filtering, business process automation (BPA) and predictive maintenance.

- Classical ML is often categorized by how an algorithm learns to become more accurate in its predictions. There are four basic approaches: supervised learning, unsupervised learning, semi-supervised learning and reinforcement learning.

- Deep Learning (DL):

- Subset of machine learning, Deep Learning enabled much smarter results than were originally possible with ML. Face recognition is a good example.

- DL makes use of layers of information processing, each gradually learning more and more complex representations of data. The early layers may learn about colors, the next ones about shapes, the following about combinations of those shapes, and finally actual objects. DL demonstrated a breakthrough in object recognition.

- DL is currently the most sophisticated AI architecture we have developed.

- Computer Vision (CV):

- Computer vision is a field of artificial intelligence that enables computers and systems to derive meaningful information from digital images, videos and other visual inputs — and take actions or make recommendations based on that information.

- The most well-known case of this today is Google’s Translate, which can take an image of anything — from menus to signboards — and convert it into text that the program then translates into the user’s native language.

- Machine Vision (MV):

- Machine Vision is the ability of a computer to see; it employs one or more video cameras, analog-to-digital conversion and digital signal processing. The resulting data goes to a computer or robot controller. Machine Vision is similar in complexity to Voice Recognition.

- MV uses the latest AI technologies to give industrial equipment the ability to see and analyze tasks in smart manufacturing, quality control, and worker safety.

- Computer Vision systems can gain valuable information from images, videos, and other visuals, whereas Machine Vision systems rely on the image captured by the system’s camera. Another difference is that Computer Vision systems are commonly used to extract and use as much data as possible about an object.

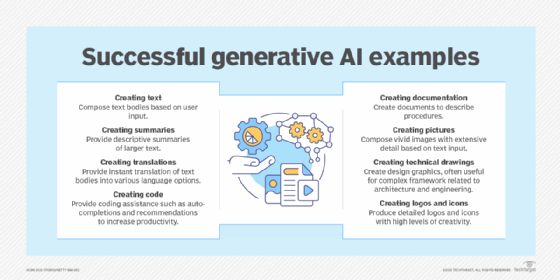

- Generative AI (GenAI):

- Generative AI technology generates outputs based on some kind of input – often a prompt supplied by a person. Some GenAI tools work in one medium, such as turning text inputs into text outputs, for example. With the public release of ChatGPT in late November 2022, the world at large was introduced to an AI app capable of creating text that sounded more authentic and less artificial than any previous generation of computer-crafted text.

- https://searchenterpriseai.techtarget.com/definition/AI-Artificial-Intelligence +

- Edge AI Technology:

- Edge artificial intelligence refers to the deployment of AI algorithms and AI models directly on local edge devices such as sensors or Internet of Things (IoT) devices, which enables real-time data processing and analysis without constant reliance on cloud infrastructure.

- Simply stated, edge AI, or “AI on the edge“, refers to the combination of edge computing and artificial intelligence to execute machine learning tasks directly on interconnected edge devices. Edge computing allows for data to be stored close to the device location, and AI algorithms enable the data to be processed right on the network edge, with or without an internet connection. This facilitates the processing of data within milliseconds, providing real-time feedback.

- Self-driving cars, wearable devices, security cameras, and smart home appliances are among the technologies that leverage edge AI capabilities to promptly deliver users with real-time information when it is most essential.

- CCTV:

- CCTV (closed-circuit television) is a TV system in which signals are not publicly distributed but are monitored, primarily for surveillance and security purposes.

- CCTV works by the camera or cameras taking a constant sequence of images that are then transmitted by cable or wirelessly (depending on the chosen system type) to the recording device and then on to the display monitor, which enables an individual to see the sequence of images as video footage.

- GNSS (Global Navigation Satellite System):

- General term describing any satellite constellation that provides positioning, navigation, and timing (PNT) services on a global or regional basis.

- GPS is traditionally refers to the North American global positioning system, or satellite positioning system. GNSS is a term that refers to the International Multi-Constellation Satellite System. So GNSS typically includes GPS, GLONASS, Baidu, Galileo, and any other constellation system.

- Digital Twin:

- Digital Twin is most commonly defined as a software representation of a physical asset, system or process designed to detect, prevent, predict, and optimize through real time analytics to deliver business value.

- A digital twin is a virtual representation of an object or system that spans its lifecycle, is updated from real-time data, and uses simulation, machine learning and reasoning to help decision-making.

- Robotic Process Automation (RPA):

- Software technology that makes it easy to build, deploy, and manage software robots that emulate humans actions interacting with digital systems and software. Just like people, software robots can do things like understand what’s on a screen, complete the right keystrokes, navigate systems, identify and extract data, and perform a wide range of defined actions. But software robots can do it faster and more consistently than people, without the need to get up and stretch or take a coffee break.

- Industry 4.0:

- Industry 4.0 has been defined as “a name for the current trend of automation and data exchange in manufacturing technologies, including cyber-physical systems, the Internet of things, cloud computing and cognitive computing and creating the smart factory”.

- Industry 4.0 aims at transforming the manufacturing and engineering sectors by introducing factories where cyber-processing systems communicate over the Internet of Things, assisting people and machinery to execute their tasks within the shortest time possible.

- Industry 4.0 technology helps you manage and optimize all aspects of your manufacturing processes and supply chain. It gives you access to the real-time data and insights you need to make smarter, faster decisions about your business, which can ultimately boost the efficiency and profitability of your entire operation.

- The Fourth Industrial Revolution (4IR) is a term coined in 2016 by Klaus Schwab, Founder and Executive Chairman of the World Economic Forum (WEF).

- 4 Industrial Revolutions:

- First Industrial Revolution: Coal in 1765.

- Second Industrial Revolution: Gas in 1870.

- Third Industrial Revolution: Electronics and Nuclear in 1969.

- Fourth Industrial Revolution: Internet and Renewable Energy in 2000.

- Industry 5.0:

- The Fifth Industrial Revolution, or 5IR, encompasses the notion of harmonious human–machine collaborations, with a specific focus on the well-being of the multiple stakeholders (i.e., society, companies, employees, customers)

- The term Industry 5.0 refers to people working alongside robots and smart machines. It’s about robots helping humans work better and faster by leveraging advanced technologies like the Internet of Things (IoT) and big data. It adds a personal human touch to the Industry 4.0 pillars of automation and efficiency.

- Industry 5.0 takes a sharp turn and directs attention to the human element. It also ‘reflects a shift from a focus on economic value to a focus on societal value, and a shift in focus from welfare to wellbeing’ (Forbes). Compared to Industry 4.0, Industry 5.0 is…

- Dedicated to both customer and employee experience

- Acknowledging social and economic challenges

- Putting great attention on human well-being and sustainability

- Providing ‘a vision of industry that aims beyond efficiency and productivity as the sole goals’ (European Commission)

- It complements the existing “Industry 4.0” approach by specifically putting research and innovation at the service of the transition to a sustainable, human-centric and resilient industry.