Beckhoff – Fast and precise surface inspection of smart devices

EtherCAT-based servo technology in inspection machine for smart display devices

The grading of cell phones and tablets according to cosmetic defects determines the necessary measures for refurbishment. In its inspection machine – for both new and used smart devices – AI expert Griffyn Robotech uses PC-based control from Beckhoff for precise motion control in product handling. This enables the detection of micron-level surface defects in split seconds.

Griffyn Robotech, headquartered in Pune, India, specializes in visual inspection, robotics, and AI-based automation. With its solutions for industrial manufacturing and quality control, Griffyn caters to the automotive, telecom, pharmaceutical, FMCG, and machine tool industries.

The Deepsight inspection machine operates either stand-alone with manual product feed or in 2- to 4- machine pods with robot-assisted feeding.

Due to easy upgrade options, warranty and insurance cases, the reverse supply chain of smart display devices such as smartphones, tablet PCs, and wearable electronics is increasing day by day. Cosmetic inspection and grading is one of the crucial steps in processing returned devices because the detected optical flaws decide on the further disposition. Up to now, this has mostly been done by manual visual inspection. Although nothing beats the human eye for versatility, its repetitive accuracy and productivity are limited. In addition, millions of devices need to be inspected and graded before recirculating them in the forward supply chain every year.

To meet the increasing demand in the reverse supply chain and eliminate the subjectivity of human grading, Griffyn Robotech launched the Deepsight Cosmetic Grading Machine (CGM). The patented vision system enables fast and accurate detection, measurement, and analysis of all surface defects with high repeatability. It intelligently identifies surface defects such as scratches while tolerating natural variations in complex patterns and surface textures, including glossy, shiny, or rough surfaces. It also takes into account significant differences in tolerances that apply to the make and model of the devices.

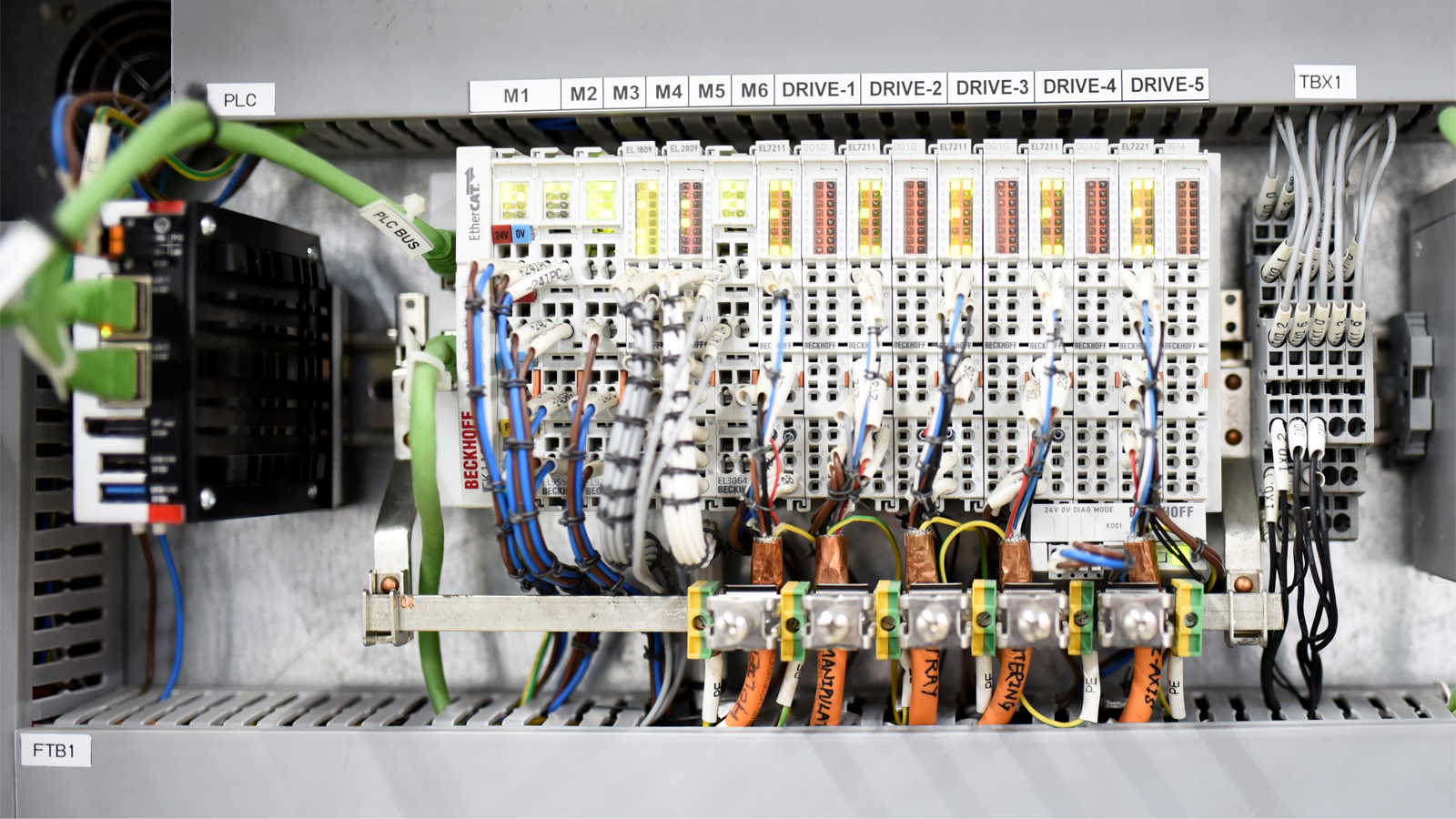

Efficient product handling reduces cycle times

The machine uses a high-resolution camera sensor to determine any handheld device’s “true” quality by capturing multiple images of all six sides of the device. However, the basis for accurate image capture is suitable product handling for flipping, turning and positioning the devices. For precise and fast motion control with accurate object orientation, Griffyn employs TwinCAT NC I motion control installed on the ultra-compact C6015 Industrial PC from Beckhoff. Combined with the AM81xx servomotors and EL7211 servomotor terminals, this enables complex multi-axis interpolated motion on a small footprint. Ultra-fast EtherCAT communication and sub-millisecond processing times reduce machine cycle times and boost throughput, according to Griffyn.

The captured images are put through Griffyn’s proprietary deep learning algorithms to identify various surface defects such as scratches, cracks, dents, and discoloration. After analysis, the machine provides a detailed report that includes raw images and a processed image highlighting defects that may not be obvious to a human operator. While the human eye can detect visible scratches larger than 80 µm wide on the surface, the Deepsight machine identifies defects as small as 40 µm in width and 3 µm in depth. The report details the number of scratches on the device, the length of the most significant scratch, and the depth of the deepest scratch.

The machine provides out-of-the-box integration with supply chain management systems, where grading data drives downstream processes and the ultimate disposition of the device. Sub-standard smartphones with defects within acceptable ranges will be directed to a buff and polish process. For example, devices with scratches less than 15 µm deep can typically be buffed and polished, resulting in a flawless upgraded device. With its high-accuracy grading data, Deepsight is able to reliably determine whether devices are good candidates for simple refurbishment or need more intensive remanufacturing.

Compact machine design as a goal

As Griffyn wanted to build a sleek, aesthetic-looking machine, they were looking for components that were as compact as possible. According to Griffyn, the compact drive technology from Beckhoff controlling the five servo axes, various EtherCAT Terminals and the ultra-compact C6015 Industrial PC really fit the bill. In addition, the One Cable Technology (OCT) of the drive components provided easy routing and installation. The TwinCAT software with its rich programming library, convenient user interface, and easy engineering and debugging made the design process very user-friendly. Excellent customer support from the local Beckhoff subsidiary facilitated the implementation.

The Deepsight cosmetic grading machine is available as a stand-alone device fed by a human operator or as a “pod” of two to four machines with automatic product feed by a robotic arm. With an inspection cycle of less than a minute, the machine has an output of four inspected devices per minute in the 4-machine pod configuration. Precise motion control technology from Beckhoff helps ensure 95% uptime of the machine with a throughput in the range of 200 devices per hour.

“Team Beckhoff understood our requirements well and gave clear assessment and recommendations of the options available with them for manufacturing Deepsight. We were impressed by the integrity, service, quality, and global customer support,” says Mr. Ameya Kandalkar, Director of Griffyn Robotech.

Source

Beckhoff

EMR Analysis

More information on Beckhoff: See the full profile on EMR Executive Services

More information on Hans Beckhoff (Managing Owner, Beckhoff Automation, Beckhoff): See the full profile on EMR Executive Services

More information on TwinCAT Software by Beckhoff: https://www.beckhoff.com/en-en/products/automation/twincat/ + On the software side, the TwinCAT (The Windows Control and Automation Technology) automation suite forms the core of the control system. The TwinCAT software system turns almost any PC-based system into a real-time control with multiple PLC, NC, CNC and/or robotics runtime systems.

TwinCAT transforms almost any PC-based system into a real-time control complete with multiple PLC, NC, CNC, and/or robotics runtime systems. The possibility of modular extensions means functional changes and additions can be made at any time. If required, the openness of the control system allows not only the integration of third-party components, but also customized retrofit solutions for existing machines and systems. This ensures flexibility and investment protection for the customer.

More information on TwinSAFE by Beckhoff: https://www.beckhoff.com/en-en/products/automation/twinsafe/?pk_campaign=AdWords-AdWordsSearch-TwinSAFE_EN&pk_kwd=twinsafe + The TwinSAFE integrated safety solution represents the consistent continuation of the open and PC-based control philosophy from Beckhoff.

Due to their modularity and versatility, the TwinSAFE terminals fit seamlessly into the Beckhoff control system.

All essential areas of automation technology are covered. TwinSAFE offers solutions in the control, I/O, motion, automation, and MX segments. All components can be combined across areas to provide a fully comprehensive security architecture for almost any customer application.

More information on Griffyn Robotech: https://griffyn.io/ + Knitting together Robotics and AI/ML technologies in a Strategic fashion that can Automate your processes and aid lights out factory with our Industry 4.0 ready Products. We are a reliable partner for manufacturing Robotic & IIoT Products/Solutions of every industry and automating their value chain with advanced technology.

More information on Mr. Ameya Kandalkar (Director, Griffyn Robotech): https://www.linkedin.com/in/ameyakandalkar/

EMR Additional Notes:

- Embedded PCs – Industrial PC (IPC):

- Embedded computer systems go by many names (Box PC, Gateway, Controller, Industrial PC, etc), but an Embedded PC is essentially any specialized computer system that is implemented as part of a larger device, intelligent system, or installation.

- Embedded Devices are less complex devices than Computers. Computers may be installed in other devices but are self-sufficient to exist. Embedded Devices only exist inside other Systems. Computers are more Difficult when used, compared to an Embedded System.

- EtherCAT:

- The Ethernet Fieldbus: https://www.ethercat.org/default.htm + EtherCAT is the open real-time Ethernet network originally developed by Beckhoff. EtherCAT sets new standards for real-time performance and topology flexibility.

- EtherCAT Technology Group:

- The worlds largest Industrial Ethernet organization with 6900 member companies: https://www.ethercat.org/en/tech_group.html + The ETG is a global organization in which OEM, End Users and Technology Providers join forces to support and promote the further technology development. The EtherCAT Technology Group keeps EtherCAT technology open for all potential users.

- Ethernet:

- Ethernet is a family of wired computer networking technologies commonly used in local area networks, metropolitan area networks and wide area networks. It was commercially introduced in 1980 and first standardized in 1983 as IEEE 802.3.

- Single Pair Ethernet (SPE):

- Single Pair Ethernet cables are copper cables that only contain one twisted pair (single pair) that they use for data transmission, for example in industrial applications.

- Describes the transmission of Ethernet over only one pair of twisted copper wires. In addition to data transmission via Ethernet, SPE also enables a simultaneous power supply of terminal devices via PoDL – Power over Data Line.

- As its name suggests, Single Pair Ethernet (SPE) cabling uses only one pair of wires to transmit data, as opposed to the two pair that have long been standard in the majority of Ethernet cabling in use worldwide.

- PoE (Power over Ethernet):

- Power over Ethernet (PoE) is the process of sending electrical power and data over copper wire. The combination of data transmission along with power supplying hardware onto the same RJ45 Ethernet connector allows for the transmission of power over the network cabling.

- As PoE technology has developed, the amount of power that can be sent over Ethernet cable has increased. IEEE-compliant PoE switches and injectors can output anywhere from 12 watts to over 70 watts of power per port.

- AI – Artificial Intelligence: https://searchenterpriseai.techtarget.com/definition/AI-Artificial-Intelligence +

- Artificial intelligence is the simulation of human intelligence processes by machines, especially computer systems. Specific applications of AI include expert systems, natural language processing, speech recognition and machine vision.

- As the hype around AI has accelerated, vendors have been scrambling to promote how their products and services use AI. Often what they refer to as AI is simply one component of AI, such as machine learning. AI requires a foundation of specialized hardware and software for writing and training machine learning algorithms. No one programming language is synonymous with AI, but a few, including Python, R and Java, are popular.

- In general, AI systems work by ingesting large amounts of labeled training data, analyzing the data for correlations and patterns, and using these patterns to make predictions about future states. In this way, a chatbot that is fed examples of text chats can learn to produce lifelike exchanges with people, or an image recognition tool can learn to identify and describe objects in images by reviewing millions of examples.

- AI programming focuses on three cognitive skills: learning, reasoning and self-correction.

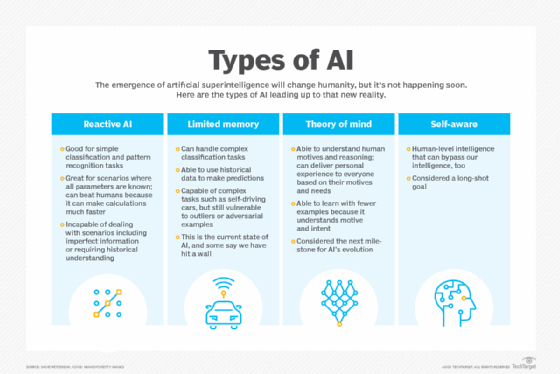

- What are the 4 types of artificial intelligence?

- Type 1: Reactive machines. These AI systems have no memory and are task specific. An example is Deep Blue, the IBM chess program that beat Garry Kasparov in the 1990s. Deep Blue can identify pieces on the chessboard and make predictions, but because it has no memory, it cannot use past experiences to inform future ones.

- Type 2: Limited memory. These AI systems have memory, so they can use past experiences to inform future decisions. Some of the decision-making functions in self-driving cars are designed this way.

- Type 3: Theory of mind. Theory of mind is a psychology term. When applied to AI, it means that the system would have the social intelligence to understand emotions. This type of AI will be able to infer human intentions and predict behavior, a necessary skill for AI systems to become integral members of human teams.

- Type 4: Self-awareness. In this category, AI systems have a sense of self, which gives them consciousness. Machines with self-awareness understand their own current state. This type of AI does not yet exist.