ABB – ABB to invest $280 million in its European Robotics hub in Sweden

- Significant upgrade of the site in Västerås follows recent investments in China and the United States

- 65,000 m2 integrated Robotics Campus replaces existing site bringing together automated manufacturing, R&D, customer experience and training centers to develop next generation AI-enabled technologies, strengthening the company’s global leadership

- Campus will strengthen ABB’s “local for local” set up increasing production capacity by 50% to enhance ABB’s ability to meet growing demand for flexible automation and robotics solutions close to its European customers

ABB today announced an investment of $280 million to expand its manufacturing footprint in Europe and build a new state-of-the-art ABB Robotics European Campus in Västerås, Sweden. The Campus will serve as the hub for ABB Robotics’ offering in Europe, providing customers with AI-enabled collaborative and industrial robots, as well as digital solutions to support flexible automation as part of the company’s “local for local” production strategy. Replacing the existing robotics facilities at the site, the new Campus is planned to open in late 2026.

“The investment in our new Campus is driven by customer demand and projected market growth,” said Björn Rosengren, ABB CEO. “Following important investments in China and the U.S, the new facility in Sweden will strengthen our capabilities in serving our customers in Europe with locally manufactured products in a growing market. Already today, around 95 percent of the robots ABB sells in the region are manufactured here. This is a strong commitment not only to our “local for local” strategy, but to all our robotics customers across Europe.”

ABB’s investment in the Robotics Campus in Västerås will enhance its robotics and automation leadership globally. With the facility, ABB will expand production capacity by 50 percent and strengthen its capabilities to supply the European market, which is expected to grow at seven percent CAGR through 20271. When the campus is completed, ABB will have invested $450 million in its three robotics facilities since 2018, including its mega factory in Shanghai that supplies customers in Asia and the Auburn Hills facility that supports the Americas.

“This is a great time to invest in robotics and automation. This new Campus is a significant part of our global growth story and key in supporting our European customers as they accelerate investment in robotics and AI due to the reshoring of industry, the move to more sustainable supply chains and long-term labor shortages,” said Sami Atiya, President of ABB’s Robotics & Discrete Automation Business Area. “Our Robotics Campus will help us to serve our customers more efficiently and support new and existing sectors like automotive, electronics, logistics, healthcare, e-commerce and pharmaceuticals to unlock the full potential of automation.”

ABB’s new Campus will enable close collaboration with customers and partners to develop robotics and automation solutions in a safe and functional environment. Customers will be able to test their solutions and experiment with the latest automation innovations on-site. In addition, employees, visitors, and students alike will be able to take part in an open and lively Campus, both during and after office hours.

“Our new, sustainable facility in Sweden will be located at the cradle of ABB Robotics’ global innovation, starting with ABB’s development of the world’s first commercial all-electric robot nearly 50 years ago”, said Marc Segura, President of ABB Robotics. “In our new R&D center, we are focusing on the development of new digital and AI-enabled technologies, making robots increasingly accessible while lowering the entry barrier for applications in all industries.”

The 65,000 m2 Campus will be a modern workplace for ABB Robotics’ workforce of 1,300 in the area and include a new factory, offices, a research and development center, an experience center and a training center for customers and visitors. The new factory will also feature autonomous mobile robots (AMRs) as a key component in transporting materials and products between the warehouse, assembly stations and assembly departments. The construction is planned to start in 2024 and will replace the nine separate buildings that have grown organically since 1974 and currently constitute the robotics operations in Sweden, thus further strengthening cross-functional synergies.

By building the Campus in Västerås, ABB continues to consolidate the area as an automation cluster, staying in important proximity to customers, suppliers, academia, and partners. The Campus will provide a unique opportunity to develop the ecosystem while maintaining rapid lead times, with shorter transports and a reduced carbon footprint. It also further allows ABB to leverage competencies and capabilities cultivated by ABB Robotics in Sweden over the past 50 years.

The campus will be constructed in line with ABB’s 2030 Sustainability Targets that aim towards carbon neutrality within ABB’s operations by reducing greenhouse gas emissions and increasing preservation of resources. To support this, consideration will be made in the selection of building materials and construction processes as well as in the use of solar panels on the roof.

1 Shipments. Source: Interact Analysis

Press conference details:

ABB will be holding a press conference in Stockholm today at 9.00am CET with Björn Rosengren, Sami Atiya and Marc Segura. To join the event online, please register via this link: https://event.vvenues.com/abb-press-conference

SourceABB

EMR Analysis

More information on ABB: See full profile on EMR Executive Services

More information on Björn Rosengren (Chief Executive Officer, ABB): See full profile on EMR Executive Services

More information on ABB Robotics & Discrete Automation: https://new.abb.com/products/robotics + ABB Robotics & Discrete Automation is the only company with a comprehensive and integrated portfolio covering robots, Autonomous Mobile Robots and machine automation solutions, designed and orchestrated by our value-creating software. We help companies of all sizes and sectors – from automotive to electronics and logistics – become more resilient, flexible and efficient. ABB Robotics & Discrete Automation supports customers in the transition towards the connected and collaborative factory of the future. The business area employs approximately 11,000 people at over 250 locations in more than 50 countries.

More information on Sami Atiya (President, Robotics & Discrete Automation and Member of the Executive Committee, ABB): See full profile on EMR Executive Services

More information on Marc Segura (President, ABB Robotics, ABB): See full profile on EMR Executive Services

More information on the ABB Sustainability Strategy: See full profile on EMR Executive Services

EMR Additional Notes:

- AI – Artificial Intelligence:

- https://searchenterpriseai.techtarget.com/definition/AI-Artificial-Intelligence +

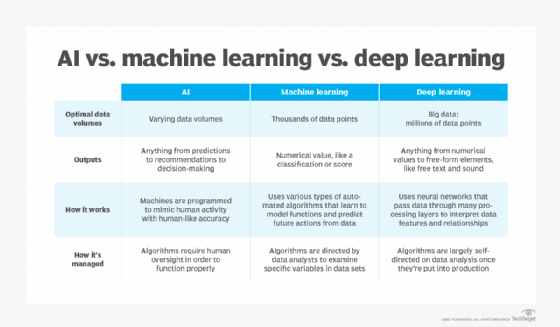

- Artificial intelligence is the simulation of human intelligence processes by machines, especially computer systems. Specific applications of AI include expert systems, natural language processing, speech recognition and machine vision.

- As the hype around AI has accelerated, vendors have been scrambling to promote how their products and services use AI. Often what they refer to as AI is simply one component of AI, such as machine learning. AI requires a foundation of specialized hardware and software for writing and training machine learning algorithms. No one programming language is synonymous with AI, but a few, including Python, R and Java, are popular.

- In general, AI systems work by ingesting large amounts of labeled training data, analyzing the data for correlations and patterns, and using these patterns to make predictions about future states. In this way, a chatbot that is fed examples of text chats can learn to produce lifelike exchanges with people, or an image recognition tool can learn to identify and describe objects in images by reviewing millions of examples.

- AI programming focuses on three cognitive skills: learning, reasoning and self-correction.

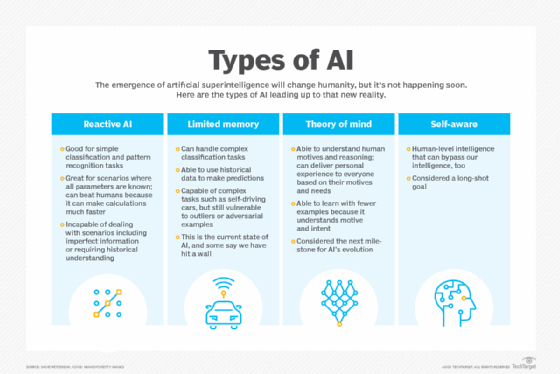

- What are the 4 types of artificial intelligence?

- Type 1: Reactive machines. These AI systems have no memory and are task specific. An example is Deep Blue, the IBM chess program that beat Garry Kasparov in the 1990s. Deep Blue can identify pieces on the chessboard and make predictions, but because it has no memory, it cannot use past experiences to inform future ones.

- Type 2: Limited memory. These AI systems have memory, so they can use past experiences to inform future decisions. Some of the decision-making functions in self-driving cars are designed this way.

- Type 3: Theory of mind. Theory of mind is a psychology term. When applied to AI, it means that the system would have the social intelligence to understand emotions. This type of AI will be able to infer human intentions and predict behavior, a necessary skill for AI systems to become integral members of human teams.

- Type 4: Self-awareness. In this category, AI systems have a sense of self, which gives them consciousness. Machines with self-awareness understand their own current state. This type of AI does not yet exist.

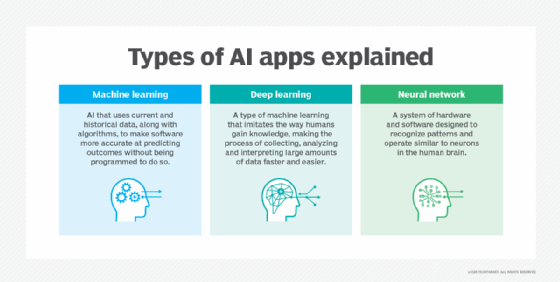

- Machine Learning:

- Developed to mimic human intelligence. It lets the machines learn independently by ingesting vast amounts of data and detecting patterns. Many ML algorithms use statistics formulas and big data to function.

- Type of artificial intelligence (AI) that allows software applications to become more accurate at predicting outcomes without being explicitly programmed to do so. Machine learning algorithms use historical data as input to predict new output values.

- Recommendation engines are a common use case for machine learning. Other popular uses include fraud detection, spam filtering, malware threat detection, business process automation (BPA) and Predictive maintenance.

- Classical machine learning is often categorized by how an algorithm learns to become more accurate in its predictions. There are four basic approaches:supervised learning, unsupervised learning, semi-supervised learning and reinforcement learning. The type of algorithm data scientists choose to use depends on what type of data they want to predict.

- Deep Learning:

- Subset of machine learning. Deep learning enabled much smarter results than were originally possible with machine learning. Consider the face recognition example.

- Deep learning makes use of layers of information processing, each gradually learning more and more complex representations of data. The early layers may learn about colors, the next ones learn about shapes, the following about combinations of those shapes, and finally actual objects. Deep learning demonstrated a breakthrough in object recognition.

- Deep learning is currently the most sophisticated AI architecture we have developed.

- Computer Vision:

- Computer vision is a field of artificial intelligence (AI) that enables computers and systems to derive meaningful information from digital images, videos and other visual inputs — and take actions or make recommendations based on that information.

- The most well-known case of this today is Google’s Translate, which can take an image of anything — from menus to signboards — and convert it into text that the program then translates into the user’s native language.

- https://searchenterpriseai.techtarget.com/definition/AI-Artificial-Intelligence +

- Cobots (Collaborative Robots):

- A collaborative robot, also known as a cobot, is a robot that is capable of learning multiple tasks so it can assist human beings. In contrast, autonomous robots are hard-coded to repeatedly perform one task, work independently and remain stationary.

- Intended to work hand-in-hand with employees. These machines focus more on repetitive tasks, such as inspection and picking, to help workers focus more on tasks that require problem-solving skills.

- A robot is an autonomous machine that performs a task without human control. A cobot is an artificially intelligent robot that performs tasks in collaboration with human workers.

- According to ISO 10218 part 1 and part 2, there are four main types of collaborative robots: safety monitored stop, speed and separation, power and force limiting, and hand guiding.

- Autonomous Mobile Robot (AMR):

- Any robot that can understand and move through its environment without being overseen directly by an operator or on a fixed predetermined path. AMRs have an array of sophisticated sensors that enable them to understand and interpret their environment, which helps them to perform their task in the most efficient manner and path possible, navigating around fixed obstructions (building, racks, work stations, etc.) and variable obstructions (such as people, lift trucks, and debris). Though similar in many ways to automated guided vehicles (AGVs), AMRs differ in a number of important ways. The greatest of these differences is flexibility: AGVs must follow much more rigid, preset routes than AMRs. Autonomous mobile robots find the most efficient route to achieve each task, and are designed to work collaboratively with operators such as picking and sortation operations, whereas AGVs typically do not.

- Automated Guided Vehicles (AGV):

- An AGV system, or automated guided vehicle system, otherwise known as an automatic guided vehicle, autonomous guided vehicle or even automatic guided cart, is a system which follows a predestined path around a facility.

- Three types of AGVs are towing, fork trucks, and heavy load carriers. Each is designed to perform repetitive actions such as delivering raw materials, keep loads stable, and complete simple tasks.

- The main difference between an AGV and an AMR is that AMRs use free navigation by means of lasers, while AGVs are located with fixed elements: magnetic tapes, magnets, beacons, etc. So, to be effective, they must have a predictable route.