ABB – ABB to expand Robotics factory in US

- Investment of $20 million will increase production at its existing Auburn Hills facility and strengthen ABB’s US leadership

- Newly expanded, highly automated facility will create new jobs in the state of Michigan

- Expansion featuring the latest in automated and advanced manufacturing processes to open November 2023

Today, ABB strengthened its commitment to one of its largest customer markets – the US – with construction starting on the expansion of its existing North American robotics headquarters and manufacturing facility in Auburn Hills, Michigan. The project is expected to be completed in November 2023 and represents an investment of $20 million. The expansion will create 72 highly skilled new jobs in the area and is supported by a $450,000 Michigan Business Development Program performance-based grant.

“Our investment is a significant step in accelerating ABB Robotics’ global leadership in developing and manufacturing cutting-edge robotic solutions in the US, for the Americas,” said Sami Atiya, President of ABB Robotics and Discrete Automation. “As the global mega trends of labor shortages, uncertainty, the near and reshoring of production, and a desire to operate more sustainably accelerate, more businesses are turning to automation to build resilience while improving efficiency and flexibility. Our expanded facility will help us to better serve customers in the US and across the Americas, giving them access to innovative automated solutions.”

Adding to the $14 billion ABB has already invested in the US since 2010, the latest investment in its Robotics headquarters and factory will benefit customers in the Americas, particularly those in growth sectors including electric vehicles, healthcare, packaging and logistics. With the expansion set to significantly increase the factory’s production capacity, it responds to the increased demand for automation from 70 percent of US businesses looking to bring production closer to home, as revealed by ABB Robotics’ survey of 1,610 executives in the US and Europe in June 2022.

“ABB’s $20 million investment creating 72 jobs will build on our economic momentum and help us continue leading the future of robotics and automation,” said Michigan Governor Gretchen Whitmer. “Thanks to companies like ABB Robotics and the support of our local partners, we can keep bringing jobs and investment to every region of our state, revitalizing communities, and building an economy of the future.”

ABB Robotics moved into the 538,000 square foot building in 1993 and opened the manufacturing plant in 2015, becoming the first global industrial robotics company to fully commit to a North American robotics production footprint. The expansion and increased use of automation in the factory will create new jobs, supporting the ABB Robotics Packaging & Logistics Headquarters in Atlanta, Georgia and the Robotics Lifesciences and Healthcare Hub located at the Texas Medical Center in Houston, Texas. ABB already has a workforce of approximately 350 employees at Auburn Hills.

ABB’s footprint in the US is more than 20,000 employees over more than 40 sites nationally.

“The expanded facility will feature the most advanced technology available, with AI-enabled robots and smart digital manufacturing systems supporting the production and manufacture of state-of-the-art customer solutions,” said John Bubnikovich, ABB United States Robotics Division President. “Almost every aspect of the site will be upgraded to enrich our efforts to attract, retain and nurture the best automation talent, while creating a US manufacturing hub and headquarters befitting of a global leader in automation.”

This investment will see the latest digital and automation technologies implemented to manufacture next generation robots in the US, for the Americas, streamlining the delivery process and reducing lead times. Close to 90 percent of robots delivered to customers in the US, Canada, Mexico and South America will soon be made in Auburn Hills. The plant will utilize flexible, modular production cells that are digitally connected and networked, and served by intelligent autonomous mobile robots. AI-powered robotic systems will take on tasks such as screw driving, assembling and material handling, relieving people from these tasks and enabling more rewarding work.

Source

ABB

EMR Analysis

More information on ABB: See full profile on EMR Executive Services

More information on Björn Rosengren (Chief Executive Office, ABB): See full profile on EMR Executive Services

More information on Sami Atiya (President Robotics & Discrete Automation and Member of the Executive Committee, ABB): See the full profile on EMR Executive Services

More information on Marc Segura (President, ABB Robotics, ABB): See the full profile on EMR Executive Services

More information on John Bubnikovich (President, ABB United States Robotics Division, ABB): See the full profile on EMR Executive Services

More information Gretchen Whitmer (Governer, Michigan, US): https://www.michigan.gov/whitmer

More information on Texas Medical Center: https://www.tmc.edu/ + Texas Medical Center (TMC) — the largest medical complex in the world — is at the forefront of advancing life sciences. Home to the brightest minds in medicine, TMC nurtures cross-institutional collaboration, creativity and innovation because together, we can push the limits of what’s possible.

More information on William F. McKeon (President & CEO, Texas Medical Center): https://www.tmc.edu/about-tmc/leadership/

EMR Additional Notes:

- AI – Artificial Intelligence: https://searchenterpriseai.techtarget.com/definition/AI-Artificial-Intelligence +

- Artificial intelligence is the simulation of human intelligence processes by machines, especially computer systems. Specific applications of AI include expert systems, natural language processing, speech recognition and machine vision.

- As the hype around AI has accelerated, vendors have been scrambling to promote how their products and services use AI. Often what they refer to as AI is simply one component of AI, such as machine learning. AI requires a foundation of specialized hardware and software for writing and training machine learning algorithms. No one programming language is synonymous with AI, but a few, including Python, R and Java, are popular.

- In general, AI systems work by ingesting large amounts of labeled training data, analyzing the data for correlations and patterns, and using these patterns to make predictions about future states. In this way, a chatbot that is fed examples of text chats can learn to produce lifelike exchanges with people, or an image recognition tool can learn to identify and describe objects in images by reviewing millions of examples.

- AI programming focuses on three cognitive skills: learning, reasoning and self-correction.

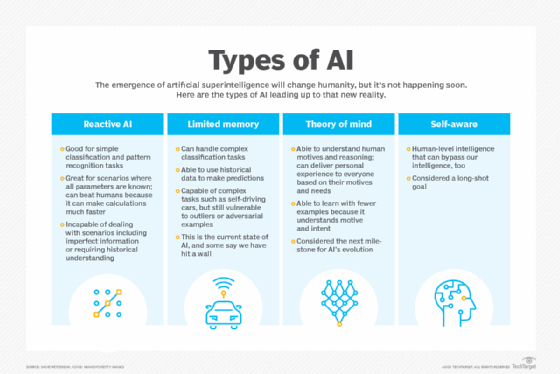

- What are the 4 types of artificial intelligence?

- Type 1: Reactive machines. These AI systems have no memory and are task specific. An example is Deep Blue, the IBM chess program that beat Garry Kasparov in the 1990s. Deep Blue can identify pieces on the chessboard and make predictions, but because it has no memory, it cannot use past experiences to inform future ones.

- Type 2: Limited memory. These AI systems have memory, so they can use past experiences to inform future decisions. Some of the decision-making functions in self-driving cars are designed this way.

- Type 3: Theory of mind. Theory of mind is a psychology term. When applied to AI, it means that the system would have the social intelligence to understand emotions. This type of AI will be able to infer human intentions and predict behavior, a necessary skill for AI systems to become integral members of human teams.

- Type 4: Self-awareness. In this category, AI systems have a sense of self, which gives them consciousness. Machines with self-awareness understand their own current state. This type of AI does not yet exist.