Siemens – Siemens partners with Airbus to decarbonize major industrial sites in the U.S. and U.K.

- Siemens to work toward the decarbonization of four Airbus industrial sites in the U.S. and U.K. as part of Airbus’ program to reduce its operational environmental footprint

- Program aims to cut energy consumption by 20 percent and Scope 1 and 2 stationary emissions by 85 percent by 2030

- Replicable solutions include renewable energy integration, smart energy management, and low-carbon heat systems, delivered in collaboration with Capgemini

Siemens and Airbus are strengthening their long-standing partnership with a new strategic contract to work toward the decarbonization of Airbus’ major industrial sites in the U.S. and U.K. The initiative is a key milestone in Airbus’ program to minimize the company’s operational environmental footprint through targeted reductions in CO2 emissions and energy consumption, among other efforts.

Left to right: Sabrina Herrmann – Head of Buildings Germany, Siemens Smart Infrastructure; Benoit Shultz – Chief Procurement Officer, Airbus; Herbert Klipp – Corporate Account Manager, Siemens; Carl Ennis – CEO Siemens UK & Ireland; Jan Schwarz – Vice President Real Estate & Facility Management Procurement, Airbus; Florent Massou dit Labaquère, EVP Operations Commercial Aircraft, Airbus; Carsten Liesener – Global Head Sales & Operations, Siemens Smart Infrastructure; Charles Huguet – Senior Vice President General Procurement, Airbus

As part of the framework agreement, Siemens will deploy its scalable and proven decarbonization solutions, tailored to the selected sites, to support Airbus in reaching the target of 80 kt CO2e abated annually from 2030.

The project will be led by Siemens’ Buildings business and supported by Capgemini, combining the companies’ vast expertise in sustainability and digitalization to ensure the success and timely delivery of the project.

Decarbonization at scale: Scalable solutions for measurable impact

Siemens will evaluate the sites and create and implement an overall decarbonization masterplan for the awarded sites, resulting in scalable solutions to reduce energy demand and carbon emissions. To accelerate the selection of the measures, Energy System Twins will simulate and help determine the best decarbonization roadmaps for the sites. The key elements that will enable this include decarbonization of heat production via heat pumps, energy efficiency upgrades, smart metering systems, on-site smart integration of renewable energy, and smart energy management systems to monitor, control, and optimize usage across the sites. These measures are designed to help Airbus achieve its targets of reducing energy consumption by 20 percent and Scope 1 and 2 greenhouse gas emissions by 85 percent through 2030, compared to 2015 levels.

Capgemini has been appointed by Siemens for the program to complete first phase consulting activities, governance definition, and support for project management and planning. Capgemini also brings its expertise in the digitalization and automation of the energy monitoring and measurement systems.

“Our collaboration with Airbus is built on years of mutual trust and shared ambition. It highlights Siemens’ capability to deliver smart and scalable technologies and services to reduce the carbon footprint of Airbus. At Siemens, we’re committed to making the energy transition not only sustainable, but also achievable and scalable, so that Airbus and other industrial leaders can confront climate challenges while boosting operational resilience and long-term competitiveness,” said Susanne Seitz, CEO of Buildings at Siemens Smart Infrastructure.

“We’re proud to be taking this important step toward making our operations more energy-efficient and future-ready. Collaborating with trusted partners is key in building a more resilient industrial footprint. The site-specific expertise from our Airbus colleagues in the U.K. and the U.S. combined with Siemens’ technical know-how will keep us on the path toward meeting our energy use and emission reduction targets,” said Florent Massou dit Labaquere, EVP Operations of Airbus Commercial Aircraft.

Roadmap to 2030

The initial phase began in summer 2025 with the development of decarbonization roadmaps for each site. Engineering studies will guide the implementation, with infrastructure rollout starting in 2026. Siemens can also operate and maintain the new infrastructure, ensuring long-term efficiency and resilience.

Siemens and Airbus have been working together for more than half a century. Key initiatives have included factory automation, industrial software, safety and security, building automation technology, and beyond. This new agreement builds on successful collaboration to support Airbus’ sustainability ambitions and achieve its targets for minimizing its operational environmental footprint.

SourceSiemens

EMR Analysis

More information on Siemens AG: See full profile on EMR Executive Services

More information on Dr. Roland Busch (President and Chief Executive Officer, Siemens AG): See full profile on EMR Executive Services

More information on Siemens Smart Infrastructure (SI) by Siemens AG: https://new.siemens.com/global/en/company/about/businesses/smart-infrastructure.html + Siemens Smart Infrastructure (SI) is shaping the market for intelligent, adaptive infrastructure for today and the future. It addresses the pressing challenges of urbanization and climate change by connecting energy systems, buildings, and industries. SI provides customers with a comprehensive end-to-end portfolio from a single source – with products, systems, solutions, and services from the point of power generation all the way to consumption. With an increasingly digitalized ecosystem, it helps customers thrive and communities progress while contributing toward protecting the planet. Siemens Smart Infrastructure has its global headquarters in Zug, Switzerland. As of September 30, 2024, the business had around 78,500 employees worldwide.

More information on Matthias Rebellius (Member of the Managing Board and Chief Executive Officer, Siemens Smart Infrastructure (SI), Siemens AG + Member of the Supervisory Board, Siemens Energy AG): See the full profile on EMR Executive Services

More information on the Buildings Business Unit by Siemens Smart Infrastructure (SI) by Siemens AG: https://www.siemens.com/global/en/products/buildings.html + The unit is a newly formed business unit which brings together all Siemens’ buildings-related businesses into one entity, effective October 1, 2024. With a combined portfolio of products, software and services, the Buildings Business Unit is a technology partner for digital transformation, focused on reliable and cost-efficient building operations, decarbonization and energy efficiency, as well as successful business operations for customers across wide-ranging industries.

The Buildings Business Unit works with customers and with an expanding ecosystem of partners across more than 60 countries and in key industries, including healthcare, data centers, higher education, commercial real estate, pharmaceutical and life science, and food and beverage. The business unit’s portfolio includes products for building control, fire safety and security, automation and operation, data-driven services, decarbonization programs and software, including Building X, Siemens’ scalable digital building platform to digitalize, manage and optimize building operations.

More information on Susanne Seitz (Chief Executive Officer, Buildings Business Unit, Siemens Smart Infrastructure (SI), Siemens AG + Member of the Supervisory Board, Siemens Quatar, Siemens AG + Member of the Board of Directors, Siemens Australia / New Zealand, Siemens AG): See the full profile on EMR Executive Services

More information on Sabrina Herrmann (Head of Buildings Germany, Buildings Business Unit, Siemens Smart Infrastructure (SI), Siemens AG): See the full profile on EMR Executive Services

More information on Herbert Klipp (Corporate Account Manager, Buildings Business Unit, Siemens Smart Infrastructure (SI), Siemens AG): See the full profile on EMR Executive Services

More information on Carl Ennis (Chief Executive Officer, Siemens Great Britain & Ireland, Siemens AG): See the full profile on EMR Executive Services

More information on Dr. Carsten Liesener (Member of the Board of Directors, R&M + Chief Executive Officer, EMEA, Siemens Smart Infrastructure (SI), Siemens AG): See the full profile on EMR Executive Services

More information on Capgemini: www.capgemini.com + Capgemini is a global business and technology transformation partner, helping organizations to accelerate their dual transition to a digital and sustainable world, while creating tangible impact for enterprises and society. It is a responsible and diverse group of 340,000 team members in more than 50 countries. With its strong over 55-year heritage, Capgemini is trusted by its clients to unlock the value of technology to address the entire breadth of their business needs. It delivers end-to-end services and solutions leveraging strengths from strategy and design to engineering, all fueled by its market leading capabilities in AI, generative AI, cloud and data, combined with its deep industry expertise and partner ecosystem. The Group reported 2024 global revenues of €22.1 billion.

More information on Aiman Ezzat (Chief Executive Officer, Capgemini): https://www.capgemini.com/about-us/management-and-governance/management-team/ + https://www.linkedin.com/in/aiman-ezzat/

More information on Airbus SE: https://www.airbus.com/en + We pioneer sustainable aerospace for a safe and united world.

Airbus is the largest aeronautics and space company in Europe, providing products, services and solutions for the commercial aircraft, helicopter, defence and space sectors. Drawing on over half a century of aerospace engineering expertise, Airbus products are defined by innovation. We are developing the next generation of aircraft to be lighter, safer and more fuel-efficient, and to fly using alternative fuel sources.

From the commercial aircraft and helicopters that connect and unite people around the world to the military aircraft and satellites that protect citizens and countries, Airbus products enable modern and connected life.

In 2024, the Company generated revenues of €69.2 billion and employed a workforce of around 157,000.

More information on Guillaume Faury (Chief Executive Officer, Airbus SE): https://www.airbus.com/en/about-us/our-governance/executive-and-operational-committees + https://www.linkedin.com/in/guillaume-faury-84a494150/

More information on Florent Massou dit Labaquère (Executive Vice President, Operations Commercial Aircraft, Airbus SE): https://www.airbus.com/en/about-us/our-governance/executive-and-operational-committees + https://www.linkedin.com/in/florent-massou-dit-labaqu%C3%A8re-7646abb/

More information on Charles Huguet (Senior Vice President, General Procurement, Airbus SE): https://www.linkedin.com/in/charles-huguet-6a3a8715/

More information on Jan Schwarz (Vice President, Real Estate & Facility Management Procurement, Airbus SE): https://www.linkedin.com/in/jan-schwarz-8092252/

More information on Benoit Shultz (Chief Procurement Officer, Airbus SE): https://www.linkedin.com/in/benoit-schultz/

EMR Additional Notes:

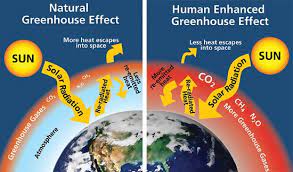

- Carbon Dioxide (CO2):

- The primary greenhouse gas emitted through human activities. Carbon dioxide enters the atmosphere through burning fossil fuels (coal, natural gas, and oil), solid waste, trees and other biological materials, and also as a result of certain chemical reactions (e.g., manufacture of cement). Carbon dioxide is removed from the atmosphere (or “sequestered”) when it is absorbed by plants as part of the biological carbon cycle.

- Biogenic Carbon Dioxide (CO2):

- Biogenic Carbon Dioxide (CO2) and Carbon Dioxide (CO2) are the same molecule. Scientists differentiate between biogenic carbon (that which is absorbed, stored and emitted by organic matter like soil, trees, plants and grasses) and non-biogenic carbon (that found in all other sources, most notably in fossil fuels like oil, coal and gas).

- CO2e (Carbon Dioxide Equivalent):

- CO2e means “carbon dioxide equivalent”. In layman’s terms, CO2e is a measurement of the total greenhouse gases emitted, expressed in terms of the equivalent measurement of carbon dioxide. On the other hand, CO2 only measures carbon emissions and does not account for any other greenhouse gases.

- A carbon dioxide equivalent or CO2 equivalent, abbreviated as CO2-eq is a metric measure used to compare the emissions from various greenhouse gases on the basis of their global-warming potential (GWP), by converting amounts of other gases to the equivalent amount of carbon dioxide with the same global warming potential.

- Carbon dioxide equivalents are commonly expressed as million metric tonnes of carbon dioxide equivalents, abbreviated as MMTCDE.

- The carbon dioxide equivalent for a gas is derived by multiplying the tonnes of the gas by the associated GWP: MMTCDE = (million metric tonnes of a gas) * (GWP of the gas).

- For example, the GWP for methane is 25 and for nitrous oxide 298. This means that emissions of 1 million metric tonnes of methane and nitrous oxide respectively is equivalent to emissions of 25 and 298 million metric tonnes of carbon dioxide.

- Carbon Footprint:

- There is no universally agreed definition of what a carbon footprint is.

- A carbon footprint is generally understood to be the total amount of greenhouse gas (GHG) emissions that are directly or indirectly caused by an individual, organization, product, or service. These emissions are typically measured in tonnes of carbon dioxide equivalent (CO2e).

- In 2009, the Greenhouse Gas Protocol (GHG Protocol) published a standard for calculating and reporting corporate carbon footprints. This standard is widely accepted by businesses and other organizations around the world. The GHG Protocol defines a carbon footprint as “the total set of greenhouse gas emissions caused by an organization, directly and indirectly, through its own operations and the value chain.”

- Decarbonization:

- Reduction of carbon dioxide emissions through the use of low carbon power sources, and achieving a lower output of greenhouse gases into the atmosphere.

- Carbon Credits or Carbon Offsets:

- Permits that allow the owner to emit a certain amount of carbon dioxide or other greenhouse gases. One credit permits the emission of one ton of carbon dioxide or the equivalent in other greenhouse gases.

- The carbon credit is half of a so-called cap-and-trade program. Companies that pollute are awarded credits that allow them to continue to pollute up to a certain limit, which is reduced periodically. Meanwhile, the company may sell any unneeded credits to another company that needs them. Private companies are thus doubly incentivized to reduce greenhouse emissions. First, they must spend money on extra credits if their emissions exceed the cap. Second, they can make money by reducing their emissions and selling their excess allowances.

- Carbon Capture and Storage (CCS) – Carbon Capture, Utilisation and Storage (CCUS):

- CCS involves the capture of carbon dioxide (CO2) emissions from industrial processes. This carbon is then transported from where it was produced, via ship or in a pipeline, and stored deep underground in geological formations.

- CCS projects typically target 90 percent efficiency, meaning that 90 percent of the carbon dioxide from the power plant will be captured and stored.

- CCUS adds the utilization aspect, where the captured CO2 is used as a new product or raw material.

- Carbon Dioxide Removal (CDR) or Durable Carbon Removal:

- Carbon Dioxide Removal encompasses approaches and methods for removing CO2 from the atmosphere and then storing it permanently in underground geological formations, in biomass, oceanic reservoirs or long-lived products in order to achieve negative emissions.

- Direct Air Capture (DAC):

- Technologies that extract CO2 directly from the atmosphere at any location, unlike carbon capture which is generally carried out at the point of emissions, such as a steel plant.

- Constraints like costs and energy requirements as well as the potential for pollution make DAC a less desirable option for CO2 reduction. Its larger land footprint when compared to other mitigation strategies like carbon capture and storage systems (CCS) also put it at a disadvantage.

- Direct Air Capture and Storage (DACCS):

- Climate technology that removes carbon dioxide (CO2) directly from the ambient atmosphere using large fans and chemical processes to bind with the CO2.

- Bioenergy with Carbon Capture and Storage (BECCS):

- Negative emissions technology that captures carbon dioxide (CO2) from biomass used for energy production and stores it permanently. Plants absorb CO2 from the atmosphere as they grow (photosynthesis), and BECCS interrupts the cycle by capturing this biogenic CO2 during the energy conversion process—burning, fermentation, etc.—instead of letting it re-enter the atmosphere.

- Enhanced Rock Weathering (ERW):

- Carbon dioxide removal (CDR) technique that accelerates the natural process of rock weathering by grinding silicate rocks into dust and spreading it on land, typically agricultural fields. This process uses rainwater to convert atmospheric carbon dioxide into mineral carbonates, which are then stored long-term in soils, groundwater, and oceans.

- Limits of Carbon Dioxide Storage:

- Carbon storage is not endless; the Earth’s capacity for permanently storing vast amounts of captured carbon, particularly in geological formations, is limited, potentially reaching a critical limit of 1,460 gigatonnes at around 2200, though storage durations vary significantly depending on the method, from decades for some biological methods to potentially millions of years for others like mineralization. While some methods offer very long-term storage, the sheer volume needed to meet climate targets requires scaling up storage significantly beyond current capacity, raising concerns about the available volume over time.

- Global Warming:

- Global warming is the long-term heating of Earth’s climate system observed since the pre-industrial period (between 1850 and 1900) due to human activities, primarily fossil fuel burning, which increases heat-trapping greenhouse gas levels in Earth’s atmosphere.

- Global Warming Potential (GWP):

- The heat absorbed by any greenhouse gas in the atmosphere, as a multiple of the heat that would be absorbed by the same mass of carbon dioxide (CO2). GWP is 1 for CO2. For other gases it depends on the gas and the time frame.

- Carbon dioxide equivalent (CO2e or CO2eq or CO2-e) is calculated from GWP. For any gas, it is the mass of CO2 which would warm the earth as much as the mass of that gas. Thus it provides a common scale for measuring the climate effects of different gases. It is calculated as GWP times mass of the other gas. For example, if a gas has GWP of 100, two tonnes of the gas have CO2e of 200 tonnes.

- GWP was developed to allow comparisons of the global warming impacts of different gases.

- Greenhouse Gas (GHG):

- A greenhouse gas is any gaseous compound in the atmosphere that is capable of absorbing infrared radiation, thereby trapping and holding heat in the atmosphere. By increasing the heat in the atmosphere, greenhouse gases are responsible for the greenhouse effect, which ultimately leads to global warming.

- The main gases responsible for the greenhouse effect include carbon dioxide, methane, nitrous oxide, and water vapor (which all occur naturally), and fluorinated gases (which are synthetic).

- GHG Protocol Corporate Standard Scope 1, 2 and 3: https://ghgprotocol.org/ + The GHG Protocol Corporate Accounting and Reporting Standard provides requirements and guidance for companies and other organizations preparing a corporate-level GHG emissions inventory. Scope 1 and 2 are typically mandatory for companies that are required to report their emissions by national or regional regulations. The GHG Protocol itself is a voluntary standard.

- Scope 1: Direct emissions:

- Direct emissions from company-owned and controlled resources. In other words, emissions are released into the atmosphere as a direct result of a set of activities, at a firm level. It is divided into four categories:

- Stationary combustion (e.g from fuels, heating sources). All fuels that produce GHG emissions must be included in scope 1.

- Mobile combustion is all vehicles owned or controlled by a firm, burning fuel (e.g. cars, vans, trucks). The increasing use of “electric” vehicles (EVs), means that some of the organisation’s fleets could fall into Scope 2 emissions.

- Fugitive emissions are leaks from greenhouse gases (e.g. refrigeration, air conditioning units). It is important to note that refrigerant gases are a thousand times more dangerous than CO2 emissions. Companies are encouraged to report these emissions.

- Process emissions are released during industrial processes, and on-site manufacturing (e.g. production of CO2 during cement manufacturing, factory fumes, chemicals).

- Direct emissions from company-owned and controlled resources. In other words, emissions are released into the atmosphere as a direct result of a set of activities, at a firm level. It is divided into four categories:

- Scope 2: Indirect emissions – owned:

- Indirect emissions from the generation of purchased energy, from a utility provider. In other words, all GHG emissions released in the atmosphere, from the consumption of purchased electricity, steam, heat and cooling. For most organisations, electricity will be the unique source of scope 2 emissions. Simply stated, the energy consumed falls into two scopes: Scope 2 covers the electricity consumed by the end-user. Scope 3 covers the energy used by the utilities during transmission and distribution (T&D losses).

- Scope 3: Indirect emissions – not owned:

- Indirect emissions – not included in scope 2 – that occur in the value chain of the reporting company, including both upstream and downstream emissions. In other words, emissions are linked to the company’s operations. According to the GHG protocol, scope 3 emissions are separated into 15 categories.

- Scope 1: Direct emissions:

- Digital Twin:

- Digital Twin is most commonly defined as a software representation of a physical asset, system or process designed to detect, prevent, predict, and optimize through real time analytics to deliver business value.

- A digital twin is a virtual representation of an object or system that spans its lifecycle, is updated from real-time data, and uses simulation, machine learning and reasoning to help decision-making.

- Heat Exchangers, Heat Pumps, Air Source Heat Pump (ASHP), Hydronics, Geothermal Heating – Cooling & Chillers:

- Heat Exchangers:

- Used to transfer heat from one medium to another. These media may be a gas, liquid, or a combination of both. The media may be separated by a solid wall to prevent mixing or may be in direct contact. Heat exchangers are required to provide heating and/or cooling to meet a process requirement.

- In HVAC, Heat exchangers are used to transfer heat between the indoor and outdoor air streams while keeping them physically separated as a means of cooling the indoor air. In addition, heat exchangers can also be used to heat indoor air. These systems are called heat pumps.

- Heat Pumps:

- Use electricity to transfer heat from a cool space to a warm space, making the cool space cooler and the warm space warmer. During the heating season, heat pumps move heat from the cool outdoors into your warm house. During the cooling season, heat pumps move heat from your house into the outdoors. Because they transfer heat rather than generate heat, heat pumps can efficiently provide comfortable temperatures for your home.

- Air Source Heat Pump (ASHP):

- Heating and cooling system that extracts heat from the outside air and transfers it to a building’s interior for heating, or reverses the process to cool the building. ASHPs are a low-carbon alternative to traditional heating systems like gas boilers or oil furnaces. They are efficient because they transfer heat rather than generating it, typically providing 2-4 times more heat energy than the electricity they consume.

- The only difference between a heat pump and a chiller is that one is designed to remove heat from a space or process stream, making it cooler and rejecting heat to the environment, while the other is designed to extract heat from the environment and use it to provide useful heat.

- Hydronics:

- Systems of heating or cooling that involves transfer of heat by a circulating fluid (such as water or vapor) in a closed system of pipes.

- Geothermal Heating and Cooling Systems:

- Take advantage of the stable temperature underground using a piping system, commonly referred to as a “loop.” Water circulates in the loop to exchange heat between your home, the ground source heat pump, and the earth, providing geothermal heating, cooling, and hot water at remarkably high efficiencies.

- Chillers:

- Mechanical systems that remove heat from a building’s liquid coolant, typically water, and transfer it to another location to cool the air and maintain comfort. Unlike traditional systems that might cool air directly, chillers generate chilled water that circulates through air handling units (AHUs) within the space to absorb heat, making them essential for cooling large commercial or industrial buildings.

- Heat Exchangers:

- Advanced Metering Infrastructure (AMI):

- https://www.energy.gov/sites/prod/files/2016/12/f34/AMI%20Summary%20Report_09-26-16.pdf

- Advanced metering infrastructure (AMI) is an integrated system of smart meters, communications networks, and data management systems that enables two-way communication between utilities and customers.

- The system provides a number of important functions that were not previously possible or had to be performed manually, such as the ability to automatically and remotely measure electricity use, connect and disconnect service, detect tampering, identify and isolate outages, and monitor voltage.

- Combined with customer technologies, such as in-home displays and programmable communicating thermostats, AMI also enables utilities to offer new time-based rate programs and incentives that encourage customers to reduce peak demand and manage energy consumption and costs.

- Smart Metering:

- Smart metering is the monitoring of resource consumption, such as energy, water, gas, etc., through modern metering devices connected to the Internet via IoT technology.

- Advantages: Eliminates manual monthly meter readings. Monitors the electric system in real time. Encourages more efficient use of power resources. Provides responsive data for balancing electric loads while reducing blackouts. Enables dynamic pricing.