Siemens – Siemens acquires DownStream Technologies to expand PCB design-to-manufacturing flow

Acquisition expands Siemens’ offering in PCB design for the SMB market and enables greater process coverage, from design to manufacturing preparation

Siemens Digital Industries Software announced today that it has completed the acquisition of DownStream Technologies, a leading provider of manufacturing data preparation solutions for printed circuit board (PCB) design. This acquisition strengthens Siemens’ PCB design portfolio and expands its footprint in the electronics small and medium-sized business (SMB) market.

“The acquisition is a significant step for Siemens EDA in the mid-sized PCB market, offering DownStream’s customers improved time to market, quality, and cost efficiency,” said Mike Ellow, CEO, Siemens EDA, Siemens Digital Industries Software. “Integrating DownStream Technologies enables Siemens EDA to provide the most comprehensive and advanced manufacturing data preparation solution, helping to ensure a smooth transition from design to production within a fully digitalized and scalable electronic systems design process.”

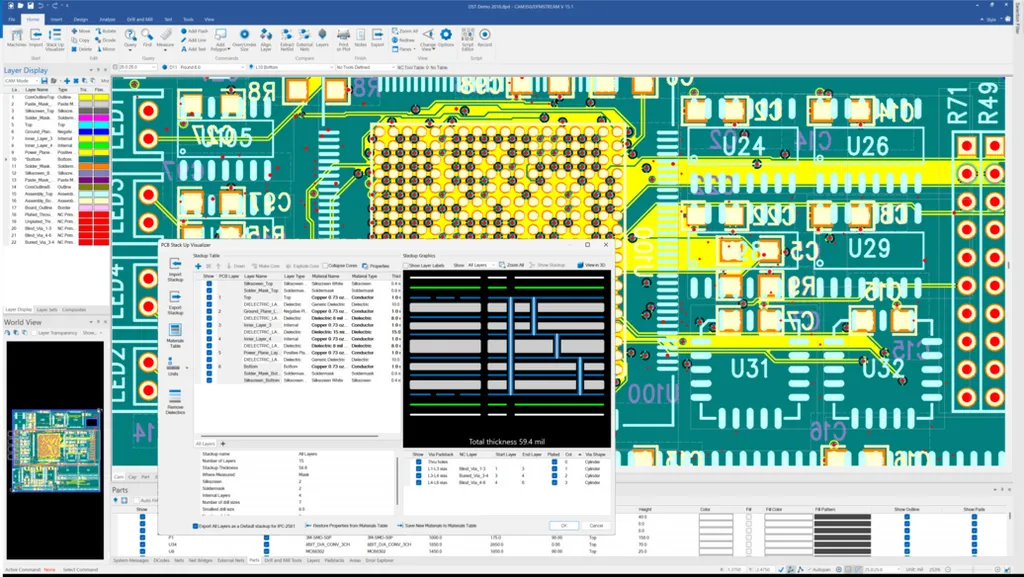

Founded in 2002 and based in Marlborough, Massachusetts, DownStream Technologies is a leading provider of manufacturing solutions for manufacturing data analysis and processing, and documenting PCB designs. Its widely adopted CAM350 suite of tools enables customers to visualize, verify and automatically prepare PCB design data for fabrication.

DownStream’s patented BluePrint-PCB tool is widely recognized as a best-in-class documentation solution enabling customers of all sizes to automate the creation of highly detailed manufacturing documents. By reducing errors and streamlining the transition from design to production, BluePrint-PCB enhances efficiency across the PCB development process. The integration of BluePrint-PCB with Siemens’ PCB design solutions aims to provide customers with a seamless workflow, improving digital continuity and manufacturing readiness.

“We’re excited to join forces with Siemens and bring our decades of expertise into their world-class ecosystem,” said Rick Almeida, founder, DownStream Technologies. “Together, we’ll provide a fully integrated solution with both breadth and depth that enables PCB designers to deliver designs to manufacturing with greater efficiency and confidence.”

Terms of the transaction, which closed on April 7, 2025, were not disclosed. To learn more about Siemens’ acquisition of DownStream Technologies, visit https://blogs.sw.siemens.com/electronic-systems-design/2025/04/08/siemens-welcomes-downstream-technologies/.

Siemens Digital Industries Software helps organizations of all sizes digitally transform using software, hardware and services from the Siemens Xcelerator business platform. Siemens’ software and the comprehensive digital twin enable companies to optimize their design, engineering and manufacturing processes to turn today’s ideas into the sustainable products of the future. From chips to entire systems, from product to process, across all Siemens Digital Industries Software – Accelerating transformation.

SourceSiemens

EMR Analysis

More information on Siemens AG: See full profile on EMR Executive Services

More information on Dr. Roland Busch (President and Chief Executive Officer, Siemens AG): See full profile on EMR Executive Services

More information on Ralf P. Thomas (Member of the Managing Board and Chief Financial Officer, Siemens AG): See full profile on EMR Executive Services

More information on Siemens Digital Industries (DI) by Siemens AG: See full profile on EMR Executive Services + https://new.siemens.com/global/en/company/about/businesses/digital-industries.html + Siemens Digital Industries (DI) empowers companies of all sizes within the process and discrete manufacturing industries to accelerate their digital and sustainability transformation across the entire value chain. Siemens’ cutting-edge automation and software portfolio revolutionizes the design, realization and optimization of products and production. And with Siemens Xcelerator – the open digital business platform – this process is made even easier, faster, and scalable. Together with our partners and ecosystem, Siemens Digital Industries enables customers to become a sustainable Digital Enterprise. Siemens Digital Industries has a workforce of around 68,000 people worldwide.

More information on Cedrik Neike (Member of the Managing Board and Chief Executive Officer, Siemens Digital Industries (DI), Siemens AG): See full profile on EMR Executive Services

More information on Siemens Digital Industries Software by Siemens Digital Industries (DI) by Siemens AG: https://www.sw.siemens.com/en-US/ + It is driving transformation to enable a digital enterprise where engineering, manufacturing and electronics design meet tomorrow. Our solutions help companies of all sizes create and leverage digital twins that provide organizations with new insights, opportunities and levels of automation to drive innovation.

Siemens Digital Industries Software and Siemens Xcelerator are transforming the everyday by giving companies like yours the agility, flexibility and adaptability to turn ideas into innovation with greater efficiency and speed.

More information on Tony Hemmelgarn (President and Chief Executive Officer, Siemens Digital Industries Software, Siemens Digital Industries (DI), Siemens AG): See full profile on EMR Executive Services

More information on Siemens EDA (Electronic Design Automation) by Siemens Digital Industries Software by Siemens Digital Industries (DI) by Siemens AG: https://eda.sw.siemens.com/en-US/ + Streamline the design, verification and manufacturing of integrated circuits (ICs) and electronic systems. To help you deliver innovations faster and become market leaders, we are committed to delivering the world’s most comprehensive portfolio of electronic design automation (EDA) services.

More information on Mike Ellow (Chief Executive Officer, Siemens EDA, Siemens Digital Industries Software, Siemens Digital Industries (DI), Siemens AG): See full profile on EMR Executive Services

More information on Xcelerator by Siemens: https://www.sw.siemens.com/en-US/digital-transformation/ + Xcelerator provides the engineering and manufacturing software, services and application development platform to blur the boundaries between industry domains. Companies can use this technology today to build the products of tomorrow. Turn complexity into your competitive advantage with Xcelerator.

Siemens Xcelerator consists of three pillars:

- Portfolio: A curated, modular portfolio of IOT-enabled hardware and software based on standard application programming interfaces, facilitating the integration of information technology (IT) and operational technology (OT).

- Ecosystem: A growing ecosystem of partners.

- Marketplace: Interactions and transactions among customers, part

More information on DownStream Technologies by Siemens AG: https://www.downstreamtech.com/ + Founded in 2002 and based in Marlborough, Massachusetts, DownStream Technologies, LLC is a software and services company focused on helping high-tech engineering organizations optimize and automate the PCB Release Process. We deliver a truly integrated manufacturing data preparation platform. Our solutions allow engineering and manufacturing teams to work together to transition Printed Circuit Boards (PCB) designs into successful, physical PCBs, faster and without compromise.

DownStream’s solutions are the defacto standard for engineering professionals to post process PCB designs. Our tools help to create and distribute all the deliverables required for a complete PCB manufacturing and assembly release package.

More information on Richard A. Almeida (Founding Partner Responsible for Company Strategy and Direction as well as Corporate Communications and Product Marketing, DownStream Technologies, Siemens AG): See full profile on EMR Executive Services

More information on Joseph G. Clark (Founding Partner Responsible for Sales and Finance, DownStream Technologies, Siemens AG): See full profile on EMR Executive Services

More information on Kenneth Tepper (Founding Partner Responsible for Research and Development, Operations, and Technical Support, DownStream Technologies, Siemens AG): See full profile on EMR Executive Services

EMR Additional Notes:

- Printed Circuit Board (PCB) & PCB Terminal Block Relay:

- A printed circuit board (PCB) is an electronic assembly that uses copper conductors to create electrical connections between components. PCBs also provide mechanical support for electronic components so that a device can be mounted in an enclosure.

- The Printed Circuit Board (PCB) is very important in all electronic gadgets, which are used either for domestic use or for industrial purposes. PCB design services are used to design the electronic circuits. Apart from electrically connecting, it also gives mechanical support to the electrical components.

- Relays are electric switches that use electromagnetism to convert small electrical stimuli into larger currents. These conversions occur when electrical inputs activate electromagnets to either form or break existing circuits.

- A simple electromagnetic relay is made up of a solenoid, which is wire coiled around a soft iron core, an iron yoke that provides a low reluctance path for magnetic flux, a movable iron frame, and one or more sets of contacts. The three main types of relays are electromechanical, solid-state, and reed.

- The electromagnetic PCB relay works by applying an electromagnetic field when power gets applied to the coil, subsequently causing the movement of the armature and making the contacts either close or open. PCB relays get classified by construction, mounting type, or function.

- PCB terminal block connectors are designed using one-piece board mount terminal blocks and two-piece plug connectors with mating right angle and straight shrouded headers. Assembly is made simpler due to our built-in interlocks on the modular housing types.

- PCB terminal blocks enable the easy and safe transmission of signals, data, and power to the PCB. They are suitable for a variety of applications in numerous industries, markets, and for Industry 4.0 applications.

- Relay:

- Relays are electrically operated switches that open and close the circuits by receiving electrical signals from outside sources.

- Relays are the switches which aim at closing and opening the circuits electronically as well as electromechanically. It controls the opening and closing of the circuit contacts of an electronic circuit.

- Safety Relay:

- Safety relays are used to reduce risk: when a fault occurs and when detection zones are violated, they initiate a safe, reliable response. Safety relays are encountered in almost every area of mechanical engineering, mainly where the number of safety functions is quite manageable.

- A safety relay includes force-guided contacts like locked, positive, or captive-guided contacts. Normal relays include electrically conductive metal pieces. Safety relays are available in specific colors like yellow. Normal relays are not available in a specific color.

- Reed Relay:

- A reed relay is a type of relay that uses an electromagnet to control one or more reed switches. The contacts are of magnetic material and the electromagnet acts directly on them without requiring an armature to move them. Sealed in a long, narrow glass tube, the contacts are protected from corrosion.

- Monitoring Relay:

- A Monitoring Relay is a protective control device. The basic functions are to receive input signals, monitor and determine them, and output an alarm signal if a set value (threshold) is reached.

- To determine if a phase imbalance is present, the relay monitors each of the phases to detect when the voltage in any one phase falls by a predetermined amount below the average of all three phases. Similarly, if complete loss of a phase is detected, the relay will trip and disconnect power from the motor.

- Three-Phase Monitor Relays continuously monitor and detect voltage faults to protect equipment in three-phase systems. These relays retain indication and continue monitoring even with a lost phase.

- Control Relay:

- A control relay is an electrical component that opens or closes a switch in order to allow current to flow through a conducting coil, with the coil not coming into direct contact with the switch. Control relays are electromagnetic devices that typically control the power flow in circuits.

- Sequence Control Relay:

- A relay which protects the electrical system from negative sequence component is called a negative sequence relay or unbalance phase relay. The negative sequence relay protects the generator and motor from the unbalanced load which mainly occurs because of the phase-to-phase faults.

- The phase sequence relay/guard measure three phase AC supplies for correct rotation and will activate and relay output for any fault. A wrong phase sequence will cause fault in rotation or motors and pumps and can cause problems and damages. The units also monitor for phase failure and phase imbalance in the supply.

- Programmable Logic Relay:

- Programmable Logic Relays are mainly used in light industry where only a few points of I/O are needed, and cost efficiency is key. Programmable relays can be modified faster and easier than their PLC counterparts because they typically function as relays and timers only.

- Power Relay:

- Power relays open or close a circuit by using an electromagnetic coil for seamless power flow. These cost-efficient relays are manufactured with an armature, spring, and one or several contacts. If the relay is meant to be normally open (NO), when power is applied the electromagnet attracts the armature. These switches are useful in audio amplification and telephone systems. You can also use them in automotive electronics and computer systems. The objective is to relay any signal from one circuit to another.

- Small and Midsize Business (SMB):

- SMBs are usually defined by size and revenue attributes; The attribute used most often is number of employees; small businesses are usually defined as organizations with fewer than 100 employees; midsize enterprises are those organizations with 100 to 999 employees. Small business is usually defined as organizations with less than $50 million in annual revenue; midsize enterprise is defined as organizations that make more than $50 million, but less than $1 billion in annual revenue.

- EDA (Electronic Design Automation):

- Electronic Design Automation (EDA) is a specific category of hardware, software, services and processes that use computer-aided design to develop complex electronic systems like printed circuit boards, integrated circuits and microprocessors.

- Electronic Design Automation, or EDA, is a market segment consisting of software, hardware, and services with the collective goal of assisting in the definition, planning, design, implementation, verification, and subsequent manufacturing of semiconductor devices, or chips. Regarding the manufacturing of these devices, the primary providers of this service are semiconductor foundries, or fabs. These highly complex and costly facilities are either owned and operated by large, vertically integrated semiconductor companies or operated as independent, “pure-play” manufacturing service providers. This latter category has become the dominate business model.

- EDA tools play a critical role in semiconductor chip manufacturing for the following reasons: They’re used to vet semiconductor manufacturing processes to ensure they deliver the required performance and density. This part of EDA is called technology computer-aided design (TCAD).

- Blueprint:

- A blueprint is a guide for making something — it’s a design or pattern that can be followed. Want to build the best tree house ever? Draw up a blueprint and follow the design carefully. The literal meaning of a blueprint is a paper — which is blue — with plans for a building printed on it.

- After the paper was washed and dried to keep those lines from exposing, the result was a negative image of white (or whatever color the blueprint paper originally was) against a dark blue background. The resulting image was therefore appropriately named “blueprint.”.

- By definition, a blueprint is a drawing up of a plan or model. The blueprint perspective allows you to see all the pieces needed to assemble your business before you begin.

- Software vs. Hardware vs. Firmware:

- Hardware is physical: It’s “real,” sometimes breaks, and eventually wears out.

- Since hardware is part of the “real” world, it all eventually wears out. Being a physical thing, it’s also possible to break it, drown it, overheat it, and otherwise expose it to the elements.

- Here are some examples of hardware:

- Smartphone

- Tablet

- Laptop

- Desktop computer

- Printer

- Flash drive

- Router

- Software is virtual: It can be copied, changed, and destroyed.

- Software is everything about your computer that isn’t hardware.

- Here are some examples of software:

- Operating systems like Windows 11 or iOS

- Web browsers

- Antivirus tools

- Adobe Photoshop

- Mobile apps

- Firmware is virtual: It’s software specifically designed for a piece of hardware

- While not as common a term as hardware or software, firmware is everywhere—on your smartphone, your PC’s motherboard, your camera, your headphones, and even your TV remote control.

- Firmware is just a special kind of software that serves a very narrow purpose for a piece of hardware. While you might install and uninstall software on your computer or smartphone on a regular basis, you might only rarely, if ever, update the firmware on a device, and you’d probably only do so if asked by the manufacturer, probably to fix a problem.

- Hardware is physical: It’s “real,” sometimes breaks, and eventually wears out.

- Digital Twin:

- Digital Twin is most commonly defined as a software representation of a physical asset, system or process designed to detect, prevent, predict, and optimize through real time analytics to deliver business value.

- A digital twin is a virtual representation of an object or system that spans its lifecycle, is updated from real-time data, and uses simulation, machine learning and reasoning to help decision-making.

- Chip, Computer Chip and Integrated Circuit (IC):

- Assembly of electronic components in which hundreds to millions of transistors, resistors, and capacitors are interconnected and built up on a thin substrate of semiconductor material (usually silicon) to form a small chip or wafer.

- Terms are often used interchangeably but there are subtle differences:

- Chip: Is the most general term. It simply refers to a small piece of semiconductor material.

- Computer Chip: This term is more specific. It refers to a chip designed for use in computers, such as microprocessors, memory chips, and graphics processing units (GPUs).

- Integrated Circuit (IC): This is the technical term for the complex circuitry etched onto the semiconductor material. It describes the design and functionality of the electronic components on the chip.

- AI Chips:

- Artificial intelligence (AI) chips are specially designed computer microchips used in the development of AI systems. Unlike other kinds of chips, AI chips are often built specifically to handle AI tasks, such as machine learning (ML), data analysis and natural language processing (NLP).

- Chips are made of silicon, a semiconductor material.

- According to The Economist, chipmakers on the island of Taiwan produce over 60% of the world’s semiconductors and more than 90% of its most advanced chips. Unfortunately, critical shortages and a fragile geopolitical situation are constraining growth.

Nvidia, the world’s largest AI hardware and software company, relies almost exclusively on Taiwan Semiconductor Manufacturing Corporation (TSMC) for its most advanced AI chips.