Rexroth – New partners in the ctrlX World: Diversity in hardware and software continues to grow

- SEW-EURODRIVE, Emerson, Cognibotics and Schmersal are new ctrlX World Partners

- New hardware and software from the areas of drives, pneumatics, safety and programming

- ctrlX OS Ecosystem with growing solution space

Bosch Rexroth and its partners are providing an increasingly broad range of solutions at all levels of automation. The ctrlX World partner ecosystem, centered around the ctrlX AUTOMATION automation platform and the ctrlX OS operating system, is constantly growing: New additions include SEW-EURODRIVE, Emerson, Cognibotics, and Schmersal. This provides users with an ever-increasing selection of hardware, software, and apps – from digital drive control to pneumatic solutions and machine safety to intuitive development environments.

The ctrlX AUTOMATION automation system provides all the components for complete automation solutions. These include controllers, I/Os, IPCs, HMIs, safety solutions, and drives, as well as extensive motion, PLC, and IoT functionalities. With ctrlX OS, Bosch Rexroth has also developed a Linux-based, open operating system with an ecosystem that is also accessible to third-party providers—including competitors. The ctrlX World partner ecosystem continuously expands this solution space with hardware, software, and especially apps.

“Our partner world reflects the market—it grows in line with our customers’ requirements. They benefit from ever-increasing choice, shorter time-to-market, and the ability to seamlessly map entire value chains,” says Steffen Winkler, Head of Sales for the Automation & Electrification Solutions Business Unit at Bosch Rexroth.

SEW-EURODRIVE drives now part of the ctrlX OS ecosystem

SEW-EURODRIVE is another drive technology provider joining the ctrlX World. The company’s frequency inverters and gearmotors now complement the ctrlX OS ecosystem. Additional drives and an app for the ctrlX OS Store will follow. With the app, drives according to the CiA (CAN in Automation) standard, specifically the CiA 402 profile, can be conveniently controlled via a modern front end.

This gives users expanded options for drive control and diagnostics. Using hardware running ctrlX OS, multiple SEW-EURODRIVE drives can be centrally addressed, simplifying handling and increasing efficiency.

Emerson brings pneumatic and handling solutions

With its Aventics brand, Emerson is expanding the ctrlX World with powerful pneumatic and servo-electric handling solutions. This includes the IIoT-capable, modular AV valve system, which seamlessly connects to ctrlX OS. Users can comprehensively control valve functions, utilize intelligent I/O capabilities, and analyze diagnostic data in detail – an ideal basis for transparent, efficient processes.

Emerson also plans to integrate servo-electric handling systems from Aventics into the ctrlX OS ecosystem. This will enable users to precisely control motion sequences, perform targeted diagnostics, and thus achieve greater efficiency and flexibility in automated applications.

Cognibotics delivers intuitive programming with Juliet&Romeo

Cognibotics, a robotics and software specialist, is joining ctrlX World. The Juliet&Romeo programming framework significantly simplifies robot motion programming. It allows developers and engineers to create clear and easily maintainable logic – with modular design, intelligent syntax, and seamless integration into existing toolchains.

The framework runs natively on all ctrlX OS devices. It offers real-time synchronization, supports continuous integration/continuous deployment (CI/CD), and facilitates debugging and deployment. It promotes agile development processes, accelerates implementation, and shortens time to market.

Schmersal contributes components for machine safety

Schmersal is now the first pure safety solutions provider to join the ctrlX World partner ecosystem. Schmersal’s Safety Fieldbox enables the simple, decentralized connection of up to eight safety devices such as sensors, interlocks, light curtains, or emergency stop buttons via pre-assembled 8-pin M12 connectors – reducing cabling effort and errors.

The Safety Fieldbox communicates seamlessly via Safety over EtherCAT (FSoE) with the ctrlX SAFETY safety controller or ctrlX OS devices with the new Safety PLC app. It thus enables ctrlX OS-based machine solutions and easy installation and commissioning of safety components.

ctrlX World is growing rapidly

“We now have over 110 providers in ctrlX World. For our customers, this means they can combine automation solutions even more freely, scale faster, and bring innovations directly to industry,” Winkler summarizes.

Caption: The ctrlX World partner ecosystem continues to grow. Two of the new partners presented their solutions at the 7th ctrlX AUTOMATION trade press conference. From left to right: Christian Lumpe, Schmersal; Steffen Winkler, Bosch Rexroth; Stefan Schmitt; Christian Kessler; Tobias Nittel, SEW-EURODRIVE; and Hans Michael Krause, Bosch Rexroth. (Image source: Bosch Rexroth AG)

SourceRexroth

EMR Analysis

More information on Bosch Rexroth AG: See the full profile on EMR Executive Services

More information on Dr. Steffen Haack (Chairman of the Board of Management, Chief Executive Officer & Chief Technical Officer with Responsibility for Engineering Activities and the Product Area New Business, Bosch Rexroth AG): See the full profile on EMR Executive Services

More information on ctrlX World by Rexroth: https://apps.boschrexroth.com/microsites/ctrlx-automation/en/ctrlx-world/ + The most open automation system on the market

Bosch Rexroth opens up a common world for users and partners: ctrlX World. Partners introduce their own strengths and solutions via co-creation. Thus, users get a wide selection of apps and benefit from a constantly growing offer in the ctrlX Store.

More information on ctrlX AUTOMATION by Rexroth: https://apps.boschrexroth.com/microsites/ctrlx-automation/en/ + https://www.boschrexroth.com/en/de/products/industrial-solutions/electric-drives-and-controls/ctrlx-automation/ + The automation toolkit ctrlX AUTOMATION provides all components for complete automation solutions – from controllers to drives and motors as well as I/Os to Motion, PLC and IoT functionalities. With the open, modular, and scalable system, simple applications but also complex solutions can be implemented. The system is characterized by high flexibility and future-proofness. Required functions can be added to the control platform ctrlX CORE as apps at any time.

More information on Steffen Winkler (Vice President Sales, Business Unit Automation & Electrification Solutions, Bosch Rexroth AG): See the full profile on EMR Executive Services

More information on ctrlX OS by Rexroth: https://apps.boschrexroth.com/microsites/ctrlx-automation/en/portfolio/ctrlx-os/ + Linux operating system for industry.

ctrlX AUTOMATION reaches the next level when it comes to openness and freedom: In the past, our real-time-capable, Linux-based operating system was used exclusively on the control ctrlX CORE. However, ctrlX OS is now available as a separate solution for industrial environments too. It is designed for real-time use and can be used on all levels – from the field level and edge devices to the cloud.

More information on ctrlX SAFETY by Rexroth: https://apps.boschrexroth.com/microsites/ctrlx-automation/en/portfolio/ctrlx-safety/ + Safety PLC for industrial automation – small, agile, and flexible.

Bosch Rexroth is redefining safe automation: ctrlX SAFETY is the most responsive and compact safety solution of its kind. The compact yet scalable system can be used as required – from the drive-integrated SafeMotion solution in ctrlX DRIVE to the complete control system ctrlX SAFETY.

In addition to flexible use, the advantages include a very high level of safety and efficient engineering through graphic programming of the safety PLC. In combination with ctrlX SAFETYplus, the number of digital safe inputs and outputs can be perfectly adapted to the respective solution. Both secure encoders and secure analog inputs take the system to the highest level. The combination of velocity, modularity, and technological progress makes ctrlX SAFETY a safety control system that sets standards in industrial automation.

More information on Stefan Schmitt (Head of Engineering Systems & Solutions, Virtual Engineering, Rexroth): See the full profile on EMR Executive Services

More information on Hans Michael Krause (Director, Product Management, ctrlX World, Rexroth): See the full profile on EMR Executive Services

More information on SEW-EURODRIVE: https://www.seweurodrive.com/home.html + A global family company that is leading the way in drive technology and automation.

SEW‑EURODRIVE offers innovative solutions, with products and services provided from a single source. We have a worldwide presence and are close to our customers.

- 56 countries

- 22 000 employees

- 17 production plants

- 800 research and development employees

- 92 Drive Technology Centers

- 4,5 billion euros in sales in 2023

More information on Jürgen Blickle (Owner and Chief Executive Officer, SEW-EURODRIVE): https://www.seweurodrive.com/company/about-us/management/management.html

More information on Tobias Nittel (Head of Corporate Solution Center, Electronics, SEW-EURODRIVE): https://www.linkedin.com/in/tobias-nittel-597646343/

More information on Christian Kessler (Division Manager, Digitalization & Automation, SEW-EURODRIVE): https://www.linkedin.com/in/christian-ke%C3%9Fler-631602132/

More information on Emerson: See the full profile on EMR Executive Services

More information on Lal Karsanbhai (President and Chief Executive Officer, Emerson): See the full profile on EMR Executive Services

More information on AVENTICS™ by Emerson: See the full profile on EMR Executive Services

More information on Cognibotics: https://www.cognibotics.com/en + Cognibotics was founded in 2013, as a direct spin-off from RobotLab at the faculty of engineering (LTH) at Lund University. The basic idea of the company was formulated around a concept to use data on motor torques and clamping devices to calibrate the kinematics of a robot.

Cognibotics has since then broaded our work in several EU funded projects as well as national scientific projects relating to automatic control, mechatronics and software technologies.

Supported by Lund University Innovaton System (LU Innovation), Vinnova and Lund University Holding company (LU Holding) Cognibotics has developed as a company, industrialized our offering and developed a range of commercial products and services. Today the team at Cognibotics share an extensive network of contacts with robot experts in both academia and the automation industry, in Sweden and abroad. We work with a range of companies to develop new automation concepts and expanding the range and capabilities of industrial robots.

More information on Fredrik Malmgren (Chief Executive Officer, Cognibotics): https://www.cognibotics.com/en/contact + https://www.linkedin.com/in/fredrik-malmgren-6058011/

More information on Schmersal: https://www.schmersal.com/home + The Schmersal Group develops and produces around 18,000 different switchgears and is one of the largest suppliers in the world (60 countries) with this range.

With industry expertise and qualified services, it also offers system solutions for the automation and safety of machines and plants. More than 2,000 employees in over 20 countries work every day to realise pioneering safety solutions together with customers.

The flexibility of an owner-managed medium-sized company – and the international presence of a corporate group:

That is the Schmersal Group.

More information on FDr. h.c. Dipl.-Ing. Heinz Schmersal (Chief Executive Officer, Schmersal): https://www.schmersal.com/unternehmen/die-schmersal-gruppe/wuppertal

More information on Christian Lumpe (Product Manager, Control Systems, Schmersal): https://www.schmersal.com/presse/fachbeitraege/fachbeitraege-archiv/fachbeitraege-2021 + https://www.linkedin.com/in/christian-lumpe-b298bb104/

More information on Linux®: https://www.linux.org/ + Linux® is an open source operating system (OS). An operating system is the software that directly manages a system’s hardware and resources, like CPU, memory, and storage. The OS sits between applications and hardware and makes the connections between all of your software and the physical resources that do the work.

Non-proprietary computer operating system suitable for use on personal computers.

Linux offers great speed and security, on the other hand, Windows offers great ease of use, so that even non-tech-savvy people can work easily on personal computers. Linux is employed by many corporate organizations as servers and OS for security purpose while Windows is mostly employed by business users and gamers.

More information on CiA (CAN in Automation): https://www.can-cia.org/ + CAN in Automation (CiA) is the international users’ and manufacturers’ group for CAN (Controller Area Network), internationally standardized in the ISO 11898 series. In 1992, the nonprofit association has been established. The aim is to provide an unbiased platform for future CAN-related specifications and standards.

CiA members develop and publish CiA specifications, which covers all Open Systems Interconnection (OSI) layers and applications in different domains. CiA representatives support actively the international standardization of CAN-related topics.

Additionally, CiA members promote jointly CAN technology in different markets. This includes road vehicles, off-road and off-highway vehicles, industrial automation, medical devices, rail vehicles, maritime electronics, building automation, power generation and distribution, and many others.

More information on Holger Zeltwanger (Managing Director, CiA): https://www.can-cia.org/about-us/cia-board-of-directors + https://www.linkedin.com/in/holger-zeltwanger-78187011/?locale=en_US

EMR Additional Notes:

- Hardware vs. Software vs. Firmware:

- Hardware is physical: It’s “real,” sometimes breaks, and eventually wears out.

- Since hardware is part of the “real” world, it all eventually wears out. Being a physical thing, it’s also possible to break it, drown it, overheat it, and otherwise expose it to the elements.

- Here are some examples of hardware:

- Smartphone

- Tablet

- Laptop

- Desktop computer

- Printer

- Flash drive

- Router

- Software is virtual: It can be copied, changed, and destroyed.

- Software is everything about your computer that isn’t hardware.

- Here are some examples of software:

- Operating systems like Windows 11 or iOS

- Web browsers

- Antivirus tools

- Adobe Photoshop

- Mobile apps

- Firmware is virtual: It’s software specifically designed for a piece of hardware

- While not as common a term as hardware or software, firmware is everywhere—on your smartphone, your PC’s motherboard, your camera, your headphones, and even your TV remote control.

- Firmware is just a special kind of software that serves a very narrow purpose for a piece of hardware. While you might install and uninstall software on your computer or smartphone on a regular basis, you might only rarely, if ever, update the firmware on a device, and you’d probably only do so if asked by the manufacturer, probably to fix a problem.

- Hardware is physical: It’s “real,” sometimes breaks, and eventually wears out.

- Motors, Generators and Drives:

- Motor: Mechanical or electrical device that generates the rotational or linear force used to power a machine.

- NEMA / IEC Motors: NEMA motors are commonly made with rolled steel or cast iron frames while IEC motors are commonly made with cast aluminum or cast iron frames.

- North American NEMA (National Electrical Manufacturers Association) and IEC (International Electrotechnical Commission) standards are crucial because they ensure that motors from different manufacturers are interchangeable and meet specific criteria for performance, safety, and physical dimensions.

- Servo Motor: Self-contained electrical device, that rotate parts of a machine with high efficiency and with great precision. The output shaft of this motor can be moved to a particular angle, position and velocity that a regular motor does not have. It consists of a suitable motor coupled to a sensor for position feedback. It also requires a relatively sophisticated controller.

- Shaft Grounded Motor: Electric motor that is equipped with a device to safely redirect harmful electrical currents away from its internal bearings. Without this protection, these currents can cause significant damage and lead to premature motor failure.

- NEMA / IEC Motors: NEMA motors are commonly made with rolled steel or cast iron frames while IEC motors are commonly made with cast aluminum or cast iron frames.

- Generator: Does the opposite of this, converting mechanical energy into electricity. It does not create electricity; rather, it forces the movement of existing electric charges (electrons) in a conductor to produce an electric current.

- Drive: (also often referred to as an electric controller) is the electronic device that harnesses and controls the electrical energy sent to the motor.

- By positioning a drive between the electrical supply and the motor, power is fed into the drive, and the drive then controls and regulates the power that is fed into the motor. This allows control of speed, direction, acceleration, deceleration, torque and, in some applications, position of the motor shaft.

- Motor: Mechanical or electrical device that generates the rotational or linear force used to power a machine.

- Pneumatics:

- Pneumatics is the science and technology of pressurized air—using piped, compressed air (or a similar gas, such as nitrogen) to transmit force and energy.

- Pneumatics engineering deploys compressed air to generate energy and create motion in thousands of automated applications.

- Pneumatics is similar to hydraulics, where we use water (or another liquid) to transmit force and energy in something like a bulldozer or a crane; both are examples of fluid power, but where hydraulics uses liquid, pneumatics uses gas.

- Industrial Controllers:

- Industrial control refers to the automation systems used to provide control and monitoring functionality in manufacturing and industrial facilities, encompassing various types such as process control systems, distributed control systems, and supervisory control and data acquisition systems.

- There are three types of controllers used in industrial automation:

- Programmable Logic Controllers(PLCs),

- Distributed Control System (DCSs), and

- Programmable Automation Controller (PACs).

- In PROFINET terminology any of these is called a controller.

- I/O:

- Input/Output

- Describes any operation, program, or device that transfers data to or from a computer. Typical I/O devices are printers, hard disks, keyboards, and mouses.

- IO-Link:

- IO-Link is a powerful standard, an increasingly deployed point-to-point serial communication protocol.

- It allows for the bi-directional exchange of data and is used to communicate with sensors and/or actuators.

- Extending the globally recognized PLC standard IEC 61131, it allows three types of data to be exchanged – Process data, service data, and events.

- Major sensor manufacturers and industrial manufacturing companies have joined the international IO-Link Consortium to promote the IO-Link communication protocol due to its many advantages over standard I/O.

- Embedded PCs – Industrial PC (IPC):

- An Embedded PC is a specialized computer system that is implemented as part of a larger device, intelligent system, or installation. These systems go by many names, such as Box PC, Gateway, Controller, and Industrial PC.

- Unlike a general-purpose computer that is self-sufficient and designed for a wide range of tasks, an embedded system is purpose-built to perform a specific function and is tightly integrated within a larger system. For this reason, an embedded PC is not meant to exist as a standalone device.

- Human Machine Interface (HMI):

- A Human-Machine Interface (HMI) is a user interface or dashboard that connects a person to a machine, system, or device.

- While the term can technically be applied to any screen that allows a user to interact with a device, HMI is most commonly used in the context of an industrial process.

- PLC (Programmable Logic Controller):

- Programmable Logic Controllers (PLCs) are industrial computers, with various inputs and outputs, used to control and monitor industrial equipment based on custom programming.

- Receive information from input devices or sensors, process the data, and perform specific tasks or output specific information based on pre-programmed parameters. PLCs are often used to do things like monitor machine productivity, track operating temperatures, and automatically stop or start processes. They are also often used to trigger alarms if a machine malfunctions.

- A PLC takes in inputs, whether from automated data capture points or from human input points such as switches or buttons. Based on its programming, the PLC then decides whether or not to change the output. A PLC’s outputs can control a huge variety of equipment, including motors, solenoid valves, lights, switchgear, safety shut-offs and many others.

- While a PLC can be used for motion control, it often involves difficult and complex programming. In contrast, a dedicated motion controller can be used for process automation with equal easiness.

- A PLC is a stand-alone unit that can control one or more machines and is connected to them by cables. On the other hand, in an embedded control architecture the controller — which is almost always a printed circuit board (PCB) — is located inside the machine it controls.

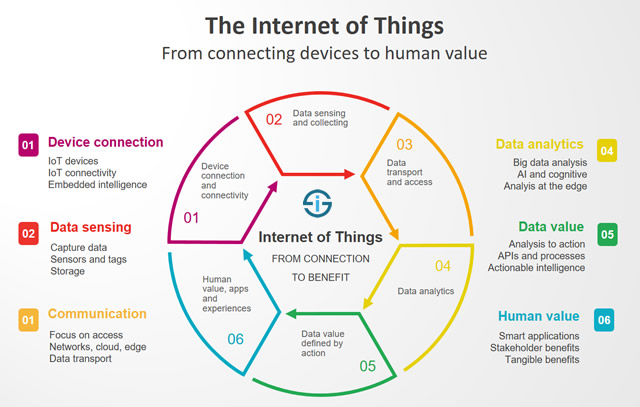

- IoT (Internet of Things):

- The Internet of Things (IoT) refers to a system of interrelated, internet-connected objects that are able to collect and transfer data over a wireless network without human intervention.

- It describes the network of physical objects—“things”—that are embedded with sensors, software, and other technologies for the purpose of connecting and exchanging data with other devices and systems over the internet.

- The Most Popular IoT Devices are:

- Smart watches.

- Smart thermostats.

- Voice-activated smart speakers and assistants.

- Smart locks and security systems.

- Fitness trackers and connected health monitors.

- Smart lighting appliances.

- IIoT (Industrial IoT):

- Industrial IoT (IIoT) involves collecting and analyzing sensor-generated data to support equipment monitoring and maintenance, production process analytics and control, and more. It applies IoT technologies specifically to industrial and manufacturing environments to improve efficiency, productivity, and safety.

- AIoT (Artificial Intelligence of Things):

- Relatively new term and has recently become a hot topic which combines two of the hottest acronyms, AI (Artificial Intelligence) and IoT (Internet of Things).

- AIoT is transformational and reciprocally beneficial for both types of technology, as AI adds value to IoT through machine learning capabilities and improved decision-making processes, while IoT adds value to AI through connectivity, signaling, and data exchange.

- Aim: achieve more efficient IoT operations, improve human-machine interactions and enhance data management and analytics.

- xIoT (xTended Internet of Things):

- xIoT refers to the “eXtended” Internet of Things. This category encompasses a broad range of connected devices, including:

- Enterprise IoT devices (cameras, printers, and door controllers).

- Operational Technology (OT) devices (like PLCs, HMIs, and robotics).

- Network devices (like switches, Wi-Fi routers, and network-attached storage).

- xIoT refers to the “eXtended” Internet of Things. This category encompasses a broad range of connected devices, including:

- Variable Speed Drive (VSD) – Variable Frequency Drive (VFD) – Inverter:

- Variable Speed Drive (VSD): Device used in electromechanical drives to control the speed and torque of an AC motor by adjusting the motor’s input frequency and voltage. Variable speed drives may be either electric, hydraulic, mechanical or even electronic.

- Variable Frequency Drive (VFD): Type of motor controller that drives an electric motor by varying the frequency and voltage supplied to the electric motor. Frequency (or hertz) is directly related to the motor’s speed (RPMs). In other words, the faster the frequency, the faster the RPMs go.

- Other names for a VFD are variable speed drive, adjustable speed drive, adjustable frequency drive, AC drive, microdrive, and inverter.

- Inverter: Device that converts direct current (DC) electricity to alternating current (AC) either for stand-alone systems or to supply power to an electricity grid.

- An inverter is one of the most important pieces of equipment in a solar energy system. It’s a device that converts direct current (DC) electricity, which is what a solar panel generates, to alternating current (AC) electricity, which the electrical grid uses.

- Crucially, an inverter is a key internal component of a Variable Frequency Drive (VFD) that performs the DC to AC conversion necessary to control the motor.

- Most inverters are installed and used in conjunction with a battery bank of some sort – a common set up in off-grid solar installations.

- => A variable frequency drive (VFD) refers to AC drives only and a variable speed drive (VSD) refers to either AC Drives or DC Drives. VFDs vary the speed of an AC motor by varying the frequency to the motor. VSDs referring to DC motors vary the speed by varying the voltage to the motor. In essence, a VFD is a specific type of VSD, and an inverter is the critical component inside a VFD that allows it to convert power and control the motor’s speed.

- Ethernet:

- Ethernet is a family of wired computer networking technologies commonly used in local area networks, metropolitan area networks and wide area networks. It was commercially introduced in 1980 and first standardized in 1983 as IEEE 802.3.

- Single Pair Ethernet (SPE):

- Single Pair Ethernet (SPE) describes the transmission of Ethernet over only one twisted pair of copper wires. This is in contrast to the two or four pairs traditionally used. In addition to data transmission, SPE also enables a simultaneous power supply to terminal devices via PoDL (Power over Data Line).

- As its name suggests, Single Pair Ethernet (SPE) cabling uses only one pair of wires to transmit data, as opposed to the two or four pairs that have long been standard in the majority of Ethernet cabling in use worldwide.

- PoE (Power over Ethernet):

- Power over Ethernet (PoE) is the process of sending both electrical power and data over a standard copper Ethernet cable. This combination of power and data onto the same RJ45 Ethernet connector allows for power to be supplied to devices without needing a separate electrical outlet.

- As PoE technology has developed, the amount of power that can be sent over Ethernet cable has increased. IEEE-compliant PoE standards can now provide a wide range of power, from around 12 watts to over 90 watts per port, depending on the standard.

- Advanced Physical Layer (APL):

- Ethernet-APL is the ruggedized, two-wire, loop-powered Ethernet physical layer that uses 10BASE-T1L plus extensions for installation within the demanding operating conditions and hazardous areas of process plants. It enables a direct connection of field devices to Ethernet-based systems in a way that process industries can benefit from a convergence of their OT and IT systems. Utilizing a switched architecture, eliminates any unwanted interference between devices connected to the same network.

- EtherCAT:

- The Ethernet Fieldbus: https://www.ethercat.org/default.htm + EtherCAT is the open, real-time Ethernet network originally developed by Beckhoff. It sets new standards for real-time performance and topology flexibility. It achieves this by processing messages on the fly and reading data as the frame passes through, without requiring the frame to be fully received and then sent on. This makes it exceptionally fast.

- EtherCAT Technology Group (ETG):

- The worlds largest Industrial Ethernet organization with 6900 member companies: https://www.ethercat.org/en/tech_group.html + The ETG is a global organization in which OEM, End Users and Technology Providers join forces to support and promote the further technology development. The EtherCAT Technology Group keeps EtherCAT technology open for all potential users.

- Single Pair Ethernet System Alliance:

- https://singlepairethernet.com/en/

- The Single Pair Ethernet System Alliance is a worldwide association of leading technology companies. We want to implement and further develop the pioneering Single Pair Ethernet technology. Together and holistically.

- The Single Pair Ethernet System Alliance is an ever-growing, collaborative community. Technology companies from all over the world jointly drive the further development of SPE technology and its implementation in various applications.

- Founding Members are: Weidmüller, Phoenix contact, Rosenberger, Datwyler, Draka and R&M.