Danfoss – Danfoss adds screw compressors to portfolio through strategic acquisition of Palladio Compressors

- Expansion of compressor portfolio supports large-scale HVAC/R systems with natural and low-GWP refrigerants

- Builds on a successful partnership with Palladio Compressors to advance high-lift heat pumps and large cooling applications

- Seamless integration of the new Danfoss Screw range to meet diverse application needs

Comprehensive expansion of compressor portfolio

In line with the Danfoss LEAP 2030 strategy, the acquisition of Palladio Compressors marks a significant expansion of our broad compressor portfolio, covering applications from light commercial comfort to large-scale process cooling, heating, and refrigeration. Over the past two years, Danfoss and Palladio have evaluated technological synergies, particularly in high-lift heat pumps. Integrating Palladio’s screw compressors with our existing technologies promises competitive and advanced high-temperature solutions.

We are thrilled to welcome Palladio Compressors and its talented team into the Danfoss family. This acquisition broadens our technological capabilities and reinforces our commitment to decarbonization across industries. Palladio’s advanced technology complements our portfolio, enhancing our compressor solutions for industrial heat pumps and large commercial and industrial refrigeration.

Fabio Klein, Divisional President, Danfoss Commercial Compressors

Expanding market reach and competitive offerings

The Palladio range introduces state-of-the-art screw technology, addressing the limited offerings of advanced, non-captive screw compressors. We are well-positioned to support customers entering new markets with compressors utilizing natural and low-GWP refrigerants. The screw technology is particularly relevant for middle-range energy intensity applications. When deciding on a suitable compressor for their systems, our customers consider factors such as size, energy intensity, and payback period requirements. Our screw offering allows us to address this uncovered middle market segment.

The newly branded Danfoss Screw range will benefit from increased investment in R&D, production, and sales capacities, ensuring robust capabilities and market presence.

By integrating screw technology into its suite of compressors, valves, controls, heat exchangers, and sensors, Danfoss reinforces its commitment to delivering greener and more efficient solutions worldwide.

Joining Danfoss is a transformative opportunity for Palladio Compressors. Together, we can leverage our combined expertise to drive innovation and expand our global reach. We are committed to providing increased options and seamless business continuity for our customers.

David Candio, CEO, Palladio Compressors

SourceDanfoss

EMR Analysis

More information on Danfoss: See the full profile on EMR Executive Services

More information on Kim Fausing (President and Chief Executive Officer, Danfoss): See the full profile on EMR Executive Services

More information on Jesper V. Christensen (Executive Vice President & Chief Financial Officer, Danfoss): See the full profile on EMR Executive Services

More information on LEAP 2030 by Danfoss: See the full profile on EMR Executive Services

More information on Danfoss Climate Solutions by Danfoss: See the full profile on EMR Executive Services

More information on Kristian Strand (Member of the Group Executive Team (GET), President, Danfoss Climate Solutions, Danfoss): See the full profile on EMR Executive Services

More information on Fabio Klein (Divisional President, Commercial Compressors, Danfoss Climate Solutions, Danfoss): See the full profile on EMR Executive Services

More information on Palladio Compressors by Danfoss Commercial Compressors by Danfoss Climate Solutions by Danfoss: https://www.palladiocompressors.com/en/ + Palladio compressors are designed and built in Italy

From the beginning of the project, we had a clear objective: to give life to something more than a simple commercial theme. We wanted a name that reflected the soul and ambition of this new adventure. After careful consideration, the choice fell on Palladio. A name that immediately evokes architecture, a field in which the balance between form and function is fundamental, just like for our compressors.

Palladio was born from the idea of proposing an innovative screw compressors project to the market, where to bring together the technical skills gained in over twenty years of compressors design and manufacturing and the experience gained by Refpower – the company where the Palladio project was started and initially developed – in the after sales field.

The result is a complete range of state-of-the-art, high-performance and reliable screw compressors for applications in the AC, in the process cooling and the industrial refrigeration sectors.

More information on David Candio (Chief Executive Officer, Palladio Compressors, Danfoss Commercial Compressors, Danfoss Climate Solutions, Danfoss): See the full profile on EMR Executive Services

EMR Additional Notes:

- Pumps and Compressors:

- A pump moves an incompressible fluid (e.g., liquid) whose volume does not (significantly) change with pressure and temperature.

- A compressor moves a compressible fluid (e.g., gas) whose volume is strongly influenced by pressure and temperature.

- Screw Compressors:

- Screw compressor technology uses two intermeshing, helical rotors—a male and a female—that rotate in opposite directions to trap and compress gas. As the rotors turn, they create and then progressively reduce the volume of chambers, drawing in gas on the intake side and discharging it at a higher pressure on the other. This positive displacement action provides continuous, non-pulsating air delivery, making screw compressors suitable for applications requiring a consistent supply of compressed air.

- HVAC-R (Heating, Ventilation, and Air Conditioning – Refrigeration):

- Heating, ventilation, and air conditioning is the use of various technologies to control the temperature, humidity, and purity of the air in an enclosed space. Its goal is to provide thermal comfort and acceptable indoor air quality.

- HVACR involves maintaining, repairing and installing heating, ventilation, air conditioning, and refrigeration systems.

- Carbon Dioxide (CO2):

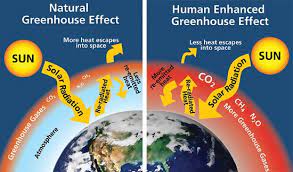

- The primary greenhouse gas emitted through human activities. Carbon dioxide enters the atmosphere through burning fossil fuels (coal, natural gas, and oil), solid waste, trees and other biological materials, and also as a result of certain chemical reactions (e.g., manufacture of cement). Carbon dioxide is removed from the atmosphere (or “sequestered”) when it is absorbed by plants as part of the biological carbon cycle.

- Biogenic Carbon Dioxide (CO2):

- Biogenic Carbon Dioxide (CO2) and Carbon Dioxide (CO2) are the same molecule. Scientists differentiate between biogenic carbon (that which is absorbed, stored and emitted by organic matter like soil, trees, plants and grasses) and non-biogenic carbon (that found in all other sources, most notably in fossil fuels like oil, coal and gas).

- CO2e (Carbon Dioxide Equivalent):

- CO2e means “carbon dioxide equivalent”. In layman’s terms, CO2e is a measurement of the total greenhouse gases emitted, expressed in terms of the equivalent measurement of carbon dioxide. On the other hand, CO2 only measures carbon emissions and does not account for any other greenhouse gases.

- A carbon dioxide equivalent or CO2 equivalent, abbreviated as CO2-eq is a metric measure used to compare the emissions from various greenhouse gases on the basis of their global-warming potential (GWP), by converting amounts of other gases to the equivalent amount of carbon dioxide with the same global warming potential.

- Carbon dioxide equivalents are commonly expressed as million metric tonnes of carbon dioxide equivalents, abbreviated as MMTCDE.

- The carbon dioxide equivalent for a gas is derived by multiplying the tonnes of the gas by the associated GWP: MMTCDE = (million metric tonnes of a gas) * (GWP of the gas).

- For example, the GWP for methane is 25 and for nitrous oxide 298. This means that emissions of 1 million metric tonnes of methane and nitrous oxide respectively is equivalent to emissions of 25 and 298 million metric tonnes of carbon dioxide.

- Carbon Footprint:

- There is no universally agreed definition of what a carbon footprint is.

- A carbon footprint is generally understood to be the total amount of greenhouse gas (GHG) emissions that are directly or indirectly caused by an individual, organization, product, or service. These emissions are typically measured in tonnes of carbon dioxide equivalent (CO2e).

- In 2009, the Greenhouse Gas Protocol (GHG Protocol) published a standard for calculating and reporting corporate carbon footprints. This standard is widely accepted by businesses and other organizations around the world. The GHG Protocol defines a carbon footprint as “the total set of greenhouse gas emissions caused by an organization, directly and indirectly, through its own operations and the value chain.”

- Decarbonization:

- Reduction of carbon dioxide emissions through the use of low carbon power sources, and achieving a lower output of greenhouse gases into the atmosphere.

- Carbon Credits or Carbon Offsets:

- Permits that allow the owner to emit a certain amount of carbon dioxide or other greenhouse gases. One credit permits the emission of one ton of carbon dioxide or the equivalent in other greenhouse gases.

- The carbon credit is half of a so-called cap-and-trade program. Companies that pollute are awarded credits that allow them to continue to pollute up to a certain limit, which is reduced periodically. Meanwhile, the company may sell any unneeded credits to another company that needs them. Private companies are thus doubly incentivized to reduce greenhouse emissions. First, they must spend money on extra credits if their emissions exceed the cap. Second, they can make money by reducing their emissions and selling their excess allowances.

- Carbon Capture and Storage (CCS) – Carbon Capture, Utilisation and Storage (CCUS):

- CCS involves the capture of carbon dioxide (CO2) emissions from industrial processes. This carbon is then transported from where it was produced, via ship or in a pipeline, and stored deep underground in geological formations.

- CCS projects typically target 90 percent efficiency, meaning that 90 percent of the carbon dioxide from the power plant will be captured and stored.

- CCUS adds the utilization aspect, where the captured CO2 is used as a new product or raw material.

- Carbon Dioxide Removal (CDR) or Durable Carbon Removal:

- Carbon Dioxide Removal encompasses approaches and methods for removing CO2 from the atmosphere and then storing it permanently in underground geological formations, in biomass, oceanic reservoirs or long-lived products in order to achieve negative emissions.

- Direct Air Capture (DAC):

- Technologies that extract CO2 directly from the atmosphere at any location, unlike carbon capture which is generally carried out at the point of emissions, such as a steel plant.

- Constraints like costs and energy requirements as well as the potential for pollution make DAC a less desirable option for CO2 reduction. Its larger land footprint when compared to other mitigation strategies like carbon capture and storage systems (CCS) also put it at a disadvantage.

- Direct Air Capture and Storage (DACCS):

- Climate technology that removes carbon dioxide (CO2) directly from the ambient atmosphere using large fans and chemical processes to bind with the CO2.

- Bioenergy with Carbon Capture and Storage (BECCS):

- Negative emissions technology that captures carbon dioxide (CO2) from biomass used for energy production and stores it permanently. Plants absorb CO2 from the atmosphere as they grow (photosynthesis), and BECCS interrupts the cycle by capturing this biogenic CO2 during the energy conversion process—burning, fermentation, etc.—instead of letting it re-enter the atmosphere.

- Enhanced Rock Weathering (ERW):

- Carbon dioxide removal (CDR) technique that accelerates the natural process of rock weathering by grinding silicate rocks into dust and spreading it on land, typically agricultural fields. This process uses rainwater to convert atmospheric carbon dioxide into mineral carbonates, which are then stored long-term in soils, groundwater, and oceans.

- Limits of Carbon Dioxide Storage:

- Carbon storage is not endless; the Earth’s capacity for permanently storing vast amounts of captured carbon, particularly in geological formations, is limited, potentially reaching a critical limit of 1,460 gigatonnes at around 2200, though storage durations vary significantly depending on the method, from decades for some biological methods to potentially millions of years for others like mineralization. While some methods offer very long-term storage, the sheer volume needed to meet climate targets requires scaling up storage significantly beyond current capacity, raising concerns about the available volume over time.

- Global Warming:

- Global warming is the long-term heating of Earth’s climate system observed since the pre-industrial period (between 1850 and 1900) due to human activities, primarily fossil fuel burning, which increases heat-trapping greenhouse gas levels in Earth’s atmosphere.

- Global Warming Potential (GWP):

- The heat absorbed by any greenhouse gas in the atmosphere, as a multiple of the heat that would be absorbed by the same mass of carbon dioxide (CO2). GWP is 1 for CO2. For other gases it depends on the gas and the time frame.

- Carbon dioxide equivalent (CO2e or CO2eq or CO2-e) is calculated from GWP. For any gas, it is the mass of CO2 which would warm the earth as much as the mass of that gas. Thus it provides a common scale for measuring the climate effects of different gases. It is calculated as GWP times mass of the other gas. For example, if a gas has GWP of 100, two tonnes of the gas have CO2e of 200 tonnes.

- GWP was developed to allow comparisons of the global warming impacts of different gases.

- Greenhouse Gas (GHG):

- A greenhouse gas is any gaseous compound in the atmosphere that is capable of absorbing infrared radiation, thereby trapping and holding heat in the atmosphere. By increasing the heat in the atmosphere, greenhouse gases are responsible for the greenhouse effect, which ultimately leads to global warming.

- The main gases responsible for the greenhouse effect include carbon dioxide, methane, nitrous oxide, and water vapor (which all occur naturally), and fluorinated gases (which are synthetic).

- GHG Protocol Corporate Standard Scope 1, 2 and 3: https://ghgprotocol.org/ + The GHG Protocol Corporate Accounting and Reporting Standard provides requirements and guidance for companies and other organizations preparing a corporate-level GHG emissions inventory. Scope 1 and 2 are typically mandatory for companies that are required to report their emissions by national or regional regulations. The GHG Protocol itself is a voluntary standard.

- Scope 1: Direct emissions:

- Direct emissions from company-owned and controlled resources. In other words, emissions are released into the atmosphere as a direct result of a set of activities, at a firm level. It is divided into four categories:

- Stationary combustion (e.g from fuels, heating sources). All fuels that produce GHG emissions must be included in scope 1.

- Mobile combustion is all vehicles owned or controlled by a firm, burning fuel (e.g. cars, vans, trucks). The increasing use of “electric” vehicles (EVs), means that some of the organisation’s fleets could fall into Scope 2 emissions.

- Fugitive emissions are leaks from greenhouse gases (e.g. refrigeration, air conditioning units). It is important to note that refrigerant gases are a thousand times more dangerous than CO2 emissions. Companies are encouraged to report these emissions.

- Process emissions are released during industrial processes, and on-site manufacturing (e.g. production of CO2 during cement manufacturing, factory fumes, chemicals).

- Direct emissions from company-owned and controlled resources. In other words, emissions are released into the atmosphere as a direct result of a set of activities, at a firm level. It is divided into four categories:

- Scope 2: Indirect emissions – owned:

- Indirect emissions from the generation of purchased energy, from a utility provider. In other words, all GHG emissions released in the atmosphere, from the consumption of purchased electricity, steam, heat and cooling. For most organisations, electricity will be the unique source of scope 2 emissions. Simply stated, the energy consumed falls into two scopes: Scope 2 covers the electricity consumed by the end-user. Scope 3 covers the energy used by the utilities during transmission and distribution (T&D losses).

- Scope 3: Indirect emissions – not owned:

- Indirect emissions – not included in scope 2 – that occur in the value chain of the reporting company, including both upstream and downstream emissions. In other words, emissions are linked to the company’s operations. According to the GHG protocol, scope 3 emissions are separated into 15 categories.

- Scope 1: Direct emissions:

- Refrigerants:

- Refrigerants are working fluids that transfer heat in cooling and heating systems like air conditioners and refrigerators by cycling between liquid and gas states to absorb heat from a cold environment and release it to a warmer one. They facilitate the cooling or freezing of objects by absorbing heat from their surroundings and moving it elsewhere, making them essential for maintaining desired temperatures in a variety of applications, from food storage to building climate control.

- Chillers:

- Mechanical systems that remove heat from a building’s liquid coolant, typically water, and transfer it to another location to cool the air and maintain comfort. Unlike traditional systems that might cool air directly, chillers generate chilled water that circulates through air handling units (AHUs) within the space to absorb heat, making them essential for cooling large commercial or industrial buildings.

- Technology Cooling System (TCS):

- Broad, non-standard term that generally refers to any integrated system, including chillers, designed to manage heat in technological applications, like data centers or industrial processes, to prevent overheating

- Condensors:

- Condenser is a heat exchanger that cools a gas or vapor, causing it to condense into a liquid, a process that releases latent heat. These devices are critical in many systems, such as air conditioning, refrigeration, and power plants, where they use air or water to absorb heat from the vapor, transforming it back into a liquid state.

- CDU (Coolant Distribution Unit):

- A coolant distribution unit contains a pump that circulates coolant through a network of pipes or channels, distributing it to various components like servers, processors, or other high heat components in large, high power devices that need cooling.

- Coolant Distribution Units are essential in data centers with high-density applications providing close controlled coolant delivery and precise control of the liquid cooling system. They help manage heat loads, reduce power consumption, and increase efficiency and reliability through redundancy.

- HDU (Heat Dissipation Unit):

- Unlike a Coolant Distribution Unit (CDU) that rejects heat from the server rack to the chilled water loop of the building, a Heat Dissipation Unit (HDU™) rejects the server heat from the server rack to the white space where building air conditioning would then remove that heat.

- RDHX (Rear Door Heat Exchanger) – Rack-level Heat Exchange:

- Chilled water cooling doors that fit onto a IT rack. The air is pulled through the rack by the fans or pushed through by the server fans for the passive rear door (no fans).