Honeywell – Honeywell to acquire Johnson Matthey’s Catalyst Technologies Business, expanding portfolio of leading catalyst and process technologies

- Unlocks strategic growth by increasing Honeywell’s installed base and creating a more integrated offering across catalyst and process technologies

- Expands Honeywell UOP’s capabilities with addition of significant installed base across refining, petrochemical and renewable fuels

- Enhances Honeywell’s existing catalyst portfolio with complementary offerings and grows renewable fuels capabilities

- Anticipated synergies with both UOP and Honeywell Process Solutions businesses, benefiting from Honeywell’s leading aftermarket capabilities

- Expected to be accretive to Honeywell’s adjusted EPS in the first full year of ownership and to add attractive high growth vectors with runway for material cost synergies

CHARLOTTE, N.C., May 22, 2025 /PRNewswire/ — Honeywell (NASDAQ: HON) today announced that it has agreed to acquire Johnson Matthey’s Catalyst Technologies business segment for £1.8 billion in an all-cash transaction, representing approximately 11x estimated 2025 EBITDA, inclusive of tax benefits and run-rate cost synergies. The combination of Johnson Matthey’s Catalyst Technologies business with Honeywell’s Energy and Sustainability Solutions (ESS) business segment is expected to add attractive high growth vectors to the portfolio and drive significant additional benefits through cost synergies.

Johnson Matthey’s Catalyst Technologies’ business model complements Honeywell’s existing UOP business of selling catalyst and process technologies and expands its installed base across refining and petrochemical catalysts. In addition, with an expanded portfolio, Honeywell will for the first time be able to offer customers a comprehensive solution for the production of lower emission, critical fuels including sustainable methanol, sustainable aviation fuel (SAF), blue hydrogen and blue ammonia, which enhance energy security and reduce emissions. The resulting offerings will provide licensed technology, engineering, services and catalysts to convert hydrocarbon and renewable feedstocks to high-value end products.

“The acquisition of Johnson Matthey’s Catalyst Technologies business broadens Honeywell’s role as a world-class technology provider of critical energy needed to drive growth into the future – further strengthening our model of combining process technologies and process automation,” said Vimal Kapur, Chairman and CEO of Honeywell. “As demand for diversified sources of energy continues accelerating, we will better enable Honeywell to offer the innovation our customers need.”

Johnson Matthey’s Catalyst Technologies business segment is a leading provider of catalyst manufacturing and process technology licensing. It has approximately 1,900 employees and is headquartered in London, United Kingdom, with sites in the U.S., Europe and India.

“As we continue to expand and evolve our ESS portfolio, acquiring Johnson Matthey’s Catalyst Technologies business will provide our customers a comprehensive and cost-effective approach to transition their businesses to high-value products with lower emissions,” said Ken West, President and CEO of Honeywell’s ESS segment. “Together, we will be able to create an integrated solution while also diversifying our UOP projects and service offerings to help our customers around the world continue innovating and driving energy security for the future.”

The acquisition is expected to be accretive to earnings in the first year and will add attractive high growth vectors to Honeywell’s ESS business.

The acquisition follows Honeywell’s announcement of the planned spin off of its Aerospace Technologies business along with the planned spin off of its Advanced Materials business, which will result in three publicly listed industry leaders with distinct strategies and growth drivers.

Since December 2023, Honeywell has announced a number of strategic actions to drive organic growth and simplify its portfolio, including approximately $11 billion of accretive acquisitions recently closed or announced: the Access Solutions business from Carrier Global, Civitanavi Systems, CAES Systems, the LNG business from Air Products, and Sundyne. In addition, Honeywell entered into an agreement to divest its Personal Protective Equipment business, which is expected to close in Q2 2025. Honeywell remains on pace to exceed its commitment to deploy at least $25 billion toward high-return capital expenditures, dividends, opportunistic share purchases and accretive acquisitions through 2025.

Honeywell’s acquisition of Johnson Matthey’s Catalyst Technologies business segment is expected to close by 1H 2026, subject to customary closing conditions, including receipt of certain regulatory approvals.

We describe many of the trends and other factors that drive our business and future results in this release. Such discussions contain forward-looking statements within the meaning of Section 21E of the Securities Exchange Act of 1934, as amended (the Exchange Act). Forward-looking statements are those that address activities, events, or developments that management intends, expects, projects, believes, or anticipates will or may occur in the future and include statements related to the proposed spin-off of the Company’s Advanced Materials business into a stand-alone, publicly traded company and the proposed separation of Automation and Aerospace. They are based on management’s assumptions and assessments in light of past experience and trends, current economic and industry conditions, expected future developments, and other relevant factors, many of which are difficult to predict and outside of our control. They are not guarantees of future performance, and actual results, developments and business decisions may differ significantly from those envisaged by our forward-looking statements. We do not undertake to update or revise any of our forward-looking statements, except as required by applicable securities law. Our forward-looking statements are also subject to material risks and uncertainties, including ongoing macroeconomic and geopolitical risks, such as lower GDP growth or recession, supply chain disruptions, capital markets volatility, inflation, and certain regional conflicts, that can affect our performance in both the near- and long-term. In addition, no assurance can be given that any plan, initiative, projection, goal, commitment, expectation, or prospect set forth in this release can or will be achieved. These forward-looking statements should be considered in light of the information included in this release, our Form 10-K and other filings with the Securities and Exchange Commission. Any forward-looking plans described herein are not final and may be modified or abandoned at any time.

This release references certain non-GAAP measures, including:

- Segment margin, which is defined as segment profit divided by net sales; segment profit, on an overall Honeywell basis, is defined as operating income, excluding stock compensation expense, pension and other postretirement service costs, amortization of acquisition-related intangibles, certain acquisition-related costs, and repositioning and other charges.

- Adjusted earnings per share, which is defined as diluted earning per share adjusted to exclude pension mark-to-market expense, amortization of acquisition-related intangibles, certain acquisition-related costs, and other items as described in reconciliations provided when we disclose adjusted earnings per share; and

- EBITDA, which we define as earnings before tax, depreciation and amortization.

Management believes that, when considered together with reported amounts, these measures are useful to investors and management in understanding our ongoing operations and in the analysis of ongoing operating trends.

Management does not consider these non-GAAP measures in isolation or as an alternative to financial measures determined in accordance with GAAP. The principal limitations of these non-GAAP financial measures are that they exclude significant expenses and income that are required by GAAP to be recognized in the consolidated financials statements. In addition, they are subject to inherent limitations as they reflect the exercise of judgments by management about which expenses and income are excluded or included in determining these non-GAAP financial measures.

SourceHoneywell

EMR Analysis

More information on Honeywell: See the full profile on EMR Executive Services

More information on Vimal Kapur (Chairman and Chief Executive Officer, Honeywell): See the full profile on EMR Executive Services

More information on Michal Stepniak (Senior Vice President and Chief Financial Officer, Honeywell): See the full profile on EMR Executive Services

More information on Honeywell Energy and Sustainability Solutions Segment (ESS) by Honeywell: https://ess.honeywell.com/us/en + With a decades-long focus on sustainability, Honeywell enables the energy evolution, improves resiliency and efficiency, reduces emissions, and facilitates the circular economy. Honeywell’s expertise in this area will continue helping solve the world’s toughest challenges across our end markets.

More information on Ken West (President and Chief Executive Officer, Energy and Sustainability Solutions Segment (ESS), Honeywell): See the full profile on EMR Executive Services

More information on Catalyst Technologies Business by Johnson Mattey (to become by Honeywell Energy and Sustainability Solutions Segment (ESS) by Honeywell): https://matthey.com/products-and-markets/pgms-and-circularity/pgm-chemicals-and-catalysts/catalysts + Johnson Matthey provides a portfolio of advanced homogenous catalysts, biocatalysts, heterogenous catalysts, and chemocatalysts for small molecule applications including for the pharmaceutical market. Our expert technical team will deliver the solutions you need for more cost effective, efficient, and sustainable chemistry.

In addition to our extensive portfolio of catalysts, we also provide services including catalyst screening, process optimisation, and custom catalyst manufacturing for your specific application. Our dedicated team can support you from the early development process to delivering the right catalyst at-scale.

Johnson Matthey’s Catalyst Technologies business segment is a leading provider of catalyst manufacturing and process technology licensing. It has approximately 1,900 employees and is headquartered in London, United Kingdom, with sites in the U.S., Europe and India.

More information on Honeywell UOP by Honeywell Energy and Sustainability Solutions Segment (ESS) by Honeywell: https://uop.honeywell.com + Over the last century, Honeywell UOP’s engineers and chemists have shaped the refining, petrochemical and gas processing industries by turning laboratory science into industrial reality.

UOP processes produce the fuels that power our cars, trucks, jets and trains. They make the natural gas that heats our homes and serves as a source of power generation. Biodegradable detergents and the plastic resins, films and fibers we use in commercial goods, packaging and fabrics are made with technologies from UOP.

UOP continues to innovate to create flexible, future-forward and sustainable solutions that address the challenges of our everchanging world. We’re striving to create cleaner fuels by developing processes that reduce emissions and produce renewable fuel sources. Our Honeywell Green Diesel™ and Honeywell Green Jet Fuel™ require no changes to engines or fuel infrastructure and reduce greenhouse gas emissions by more than two-thirds.

Our process technologies, equipment and lifecycle solutions are helping customers generate the most value from every drop of oil, every cubic foot of natural gas and every ton of coal. And through connected software, UOP is helping customers become more efficient and profitable through digital tools that ensure plants are running at the peak of their capability.

Part of Honeywell’s Performance Materials and Technologies business group, UOP has more than 3,000 active patents, a global presence, and a century of experience using breakthrough chemistry and engineering to power global growth.

More information on Air Products’ Liquefied Natural Gas Process Technology And Equipment Business by Honeywell UOP by Honeywell Energy and Sustainability Solutions Segment (ESS) by Honeywell: https://uop.honeywell.com/en/industry-solutions/gas-processing/lng/liquefaction-of-natural-gas + Process technology and equipment with proven efficiency and low project cost. After acquiring Air Products LNG, Honeywell is the world’s leading provider of natural gas liquefaction technology, coil-wound heat exchangers and related equipment and services which are valued for their proven reliability, optimum efficiency, and operational flexibility. Our experience includes the design, manufacturing and successful start-up of over 120 LNG plants.

More information on Sundyne by Honeywell Energy and Sustainability Solutions Segment (ESS) by Honeywell: https://www.sundyne.com/ + Sundyne is a leader in the design, manufacturing and aftermarket support of highly-engineered pumps and gas compressors used in process industries.

Sundyne is one of the few companies that design & manufacture both Pumps and Compressors. Through organic & inorganic growth, Sundyne has assembled industry-leading brands that provide customers with a wide range of fluid and gas handling services and solutions. Brands like Ansimag, HMD Kontro and Marelli have broadened the original Sundyne portfolio for a wider range of markets. Sundyne equipment can be built to most standards, including ANSI, ISO and API, and the line of Sunflo products offers non-standard solutions for a range of general industrial applications.

More information on Mary Zappone (Chief Executive Officer, Sundyne, Energy and Sustainability Solutions Segment (ESS), Honeywell): See the full profile on EMR Executive Services

More information on Honeywell Advanced Materials by Honeywell Energy and Sustainability Solutions Segment (ESS) by Honeywell (to be named Solstice Advanced Materials on completion of the spin): https://advancedmaterials.honeywell.com/us/en + Honeywell Advanced Materials plays a crucial role in advancing industries worldwide through diverse applications, revolutionary inventions, and pioneering technologies. Our science and technology experts create solutions that help solve our customers’ needs today and in the future. Our solutions span across industries, including Retail, Pharma, Buildings, Manufacturing and Hi-tech. In each of these verticals we bring deep materials and engineering knowledge, which leads to our customers achieving reduction in energy consumption, cutting down their carbon emissions and improving their operational efficiencies.

Solstice Advanced Materials will be a publicly traded, sustainability-focused, specialty chemicals and materials pure play. With nearly $4 billion in revenue last year, Solstice Advanced Materials will offer leading technologies with premier brands, including the Solstice® hydrofluoroolefin technology.

In addition to its headquarters in Morris Plains, New Jersey, Solstice Advanced Materials will have teams located in Charlotte, Houston, Dublin, Shanghai, Tokyo, Bangalore, Bucharest and Mexico City. The independent company will maintain its global manufacturing footprint along with additional R&D sites. With a large-scale domestic manufacturing base, Solstice Advanced Materials will be positioned to benefit from a compelling investment profile and a more flexible and optimized capital allocation strategy.

More information on Dr. Rajeev Gautam (Non-Executive Chairman of the Board of Directors, Solstice Advanced Materials effective on completion of the spin of Honeywell Advanced Materials by Honeywell Energy and Sustainability Solutions Segment (ESS) by Honeywell): See the full profile on EMR Executive Services

More information on David Sewell (President and Chief Executive Officer, Honeywell Advanced Materials, Honeywell Energy and Sustainability Solutions Segment (ESS), Honeywell): See the full profile on EMR Executive Services

More information on Honeywell Industrial Automation Segment (IA) by Honeywell: https://automation.honeywell.com/us/en + With a deep history in industrial automation that spans more than five decades, Honeywell enables process industry operations, creates world-class sensor technologies, automates supply chains, makes warehouses smarter, and improves worker safety. This combination build on our core strengths in controls and automation technologies, deliver better commercial outcomes for our customers, and enhance our growth.

More information on Lucian Boldea (President and Chief Executive Officer, Industrial Automation Segment (IA), Honeywell): See the full profile on EMR Executive Services

More information on Honeywell Process Solutions by Honeywell Industrial Automation Segment (IA) by Honeywell: https://process.honeywell.com/us/en/about-us + Honeywell Process Solutions is a pioneer in automation control, instrumentation and services for the oil and gas; refining; energy; pulp and paper; industrial power generation; chemicals and petrochemicals; biofuels; life sciences; and metals, minerals, and mining industries.

Honeywell plays a critical role across the entire lifecycle of an industrial facility, including:

- Project design and engineering

- Technology licensing

- Technical services

- Ongoing operations

- Cybersecurity

- Continuous modernization.

A leader in digitization, Honeywell delivers software and services that help customers overcome competitive pressures and uncertain market conditions to achieve game-changing business outcomes. Honeywell’s comprehensive portfolio in process control, monitoring, and safety systems and instrumentation provides optimized operations and maintenance efficiencies to meet diverse automation needs.

More information on Pramesh Maheshwari (President, Honeywell Process Solutions, Industrial Automation Segment (IA), Honeywell): See the full profile on EMR Executive Services

More information on Honeywell Personal Protective Equipment Business (part of the Sensing and Safety Technologies Business Unit) Industrial Automation Segment (IA) by Honeywell): https://ppe.honeywell.com/us/en/home + Honeywell is the worldwide leader in safety, comfort and security. We have united the most respected offerings in the safety industry to deliver an unparalleled, best-in-class retail line of personal protective equipment focused on quality and performance. Our ongoing commitment to innovation, combined with our worldwide engineering and R&D resources, have positioned us to be your premier source for the most complete solutions available. Our singular focus is to be your best safety partner, today and in the future.

The PPE business has approximately 5,000 employees and a streamlined global manufacturing and distribution footprint. It currently operates 20 manufacturing sites and 17 distribution sites across the U.S., Mexico, Europe, North Africa, Asia Pacific and China.

More information on Mike Garceau (President and Chief Executive Officer, Honeywell Personal Protective Equipment, Sensing and Safety Technologies Business Unit, Industrial Automation Segment (IA), Honeywell): See the full profile on EMR Executive Services

More information on Honeywell Aerospace Technologies Segment (AT) by Honeywell: https://aerospace.honeywell.com/ + Products and services from Honeywell Aerospace Technologies are found on virtually every commercial, defense and space aircraft. The Aerospace Technologies business unit builds aircraft engines, cockpit and cabin electronics, wireless connectivity systems, mechanical components and more. Its hardware and software solutions create more fuel-efficient aircraft, more direct and on-time flights and safer skies and airports.

More information on Jim Currier (President and Chief Executive Officer, Aerospace Technologies Segment (AT), Honeywell): See the full profile on EMR Executive Services

More information on Civitanavi Systems S.p.A. by Honeywell Aerospace Technologies Segment (AT) by Honeywell: https://www.civitanavi.com/ + Civitanavi Systems is one of the main players in the sector of high-tech inertial navigation and stabilization systems.

Thanks to a vertically integrated business model and a constant desire for technological innovation, Civitanavi excels in the design, development and production of high precision inertial navigation and stabilization systems.

The application of proprietary methods and technologies, based on FOG (Fiber Optic Gyroscope) and MEMS (Micro Electro-Mechanical Systems) technology, enables the company to best meet the specific needs of its customers, depending on the sector in question: Aerospace, Defence and Industrial.

Founded as a start-up in 2012 in Italy, Civitanavi was recognised as an innovative SME in 2017 and today is presented as a benchmark in the global competitive scenario.

The company operates from its registered office in Pedaso (on the Adriatic coast of the Marche region) and other four sites in Ardea (Rome) Casoria (Naples) and Turin with a staff of about 160 employees working throughout Italy.

More information on Andrea Pizzarulli (General Manager, Civitanavi Systems S.p.A., Aerospace Technologies Segment (AT), Honeywell): See the full profile on EMR Executive Services

More information on CAES Systems Holdings LLC by Honeywell Aerospace Technologies Segment (AT) by Honeywell: https://caes.com/ + CAES pioneers advanced electronics that underpin many of the world’s most critical missions. We design, engineer, test, and manufacture advanced electronic solutions for the U.S. aerospace and defense industry. From inception and development engineering, to full-rate production and sustainment, we work closely with customers as partners throughout the program lifecycle.

We partner with customers, co-investing in technology development and program assets to enable them to win their most strategically important programs.

Headquartered in Arlington, Virginia, with locations across the country, CAES is comprised of talented individuals who like to solve complex problems. Our employees are mission-driven and proud of the world-class products they manufacture. As a people-focused organization, we empower our employees to drive excellence in all that we do.

Headquartered in Arlington, Va., CAES (formerly known as Cobham Advanced Electronic Solutions) has 13 facilities in North America, including highly automated manufacturing facilities with fully automated test and tuning processes. The acquisition will add approximately 2,200 employees and a deep bench of RF engineering talent.

More information on Honeywell Building Automation Segment (BA) by Honeywell: https://buildings.honeywell.com/us/en/home + Through hardware, software, sensors, and analytics, Honeywell helps customers convert buildings into integrated, safe, and more sustainable assets. With solutions and services used in more than 10 million buildings worldwide, Building Automation will continue to strengthen Honeywell’s position in attractive end markets like hospitals, airports, education, and data centers.

More information on Billal Hammoud (President and Chief Executive Officer, Building Automation Segment (BA), Honeywell): See the full profile on EMR Executive Services

More information on Global Access Solutions – LenelS2 by Honeywell Building Automation Segment (BA) by Honeywell: https://www.lenels2.com/en/ + Leader in commercial and enterprise access solutions. LenelS2 is the global leader in advanced physical security solutions, including access control, video surveillance and mobile credentialing. We innovate products, systems and services to address the most complex, evolving needs of some of the world’s most demanding organizations. Whether you’re operating a small- to medium-sized business or the largest global enterprise, our solutions are built to solve your unique challenges.

More information on Global Access Solutions – Onity by Honeywell Building Automation Segment (BA) by Honeywell: https://www.onity.com/en/us/ + Electronic locks, specifically hospitality access and mobile credentials. For over 80 years, we have understood the opportunity and potential that doors hold. As a worldwide leader in the access control industry, we have continually expanded our services and solutions to become a leading provider of innovative facility technologies, including mobile access technology, electronic locking systems, and electronic in-room safes.

More information on Global Access Solutions – Supra by Honeywell Building Automation Segment (BA) by Honeywell: https://www.suprasystems.com/ + Cloud-based electronic lockboxes and scheduling software. Supra has brought efficiency and peace of mind to the real estate industry since 1955 – providing a range of leading access solutions. Today, Supra offers easy-to-use lockboxes, digital key solutions and a showing management platform that allows agents to focus on their clients.

More information on Johnson Mattey: https://matthey.com/ + Our ambition is to be a world leader in sustainable technology solutions, transforming energy and reducing carbon emissions, for a cleaner, brighter future.

ohnson Matthey has come a long way since being founded in 1817. We’re proud to say that for over two centuries, we’ve helped tackle some of the world’s biggest challenges. And we’re continuing to do so today, using our advanced metals chemistry expertise and technology solutions to enable the world’s leading energy, chemicals and automotive companies to decarbonise and reduce harmful emissions.

With global challenges of climate change, energy supply and resource scarcity more pressing than ever before, we’re making it our purpose to catalyse the net zero transition for our customers, and millions of people every day.

- Global presence: 20+ countries around the world

- World class talent: 11,600 people

- Experience 200+ year history

Following the sale of CT, JM will be repositioned as a highly streamlined group focused on Clean Air and PGMS, driving sustained strong cash generation to support attractive ongoing returns to shareholders.

More information on Liam Condon (Chief Executive Officer, Johnson Matthey): https://matthey.com/about-us/our-leadership/group-leadership-team + https://uk.linkedin.com/in/liamcondon

More information on Catalyst Technologies Business by Johnson Mattey (to become by Honeywell Energy and Sustainability Solutions Segment (ESS) by Honeywell): https://matthey.com/products-and-markets/pgms-and-circularity/pgm-chemicals-and-catalysts/catalysts + Johnson Matthey provides a portfolio of advanced homogenous catalysts, biocatalysts, heterogenous catalysts, and chemocatalysts for small molecule applications including for the pharmaceutical market. Our expert technical team will deliver the solutions you need for more cost effective, efficient, and sustainable chemistry.

In addition to our extensive portfolio of catalysts, we also provide services including catalyst screening, process optimisation, and custom catalyst manufacturing for your specific application. Our dedicated team can support you from the early development process to delivering the right catalyst at-scale.

Johnson Matthey’s Catalyst Technologies business segment is a leading provider of catalyst manufacturing and process technology licensing. It has approximately 1,900 employees and is headquartered in London, United Kingdom, with sites in the U.S., Europe and India.

More information on Maurits van Tol (Chief Executive Officer, Catalyst Technologies, Johnson Matthey): https://matthey.com/about-us/our-leadership/group-leadership-team + https://www.linkedin.com/in/mauritsvantol/

EMR Additional Notes:

- Industrial Automation:

- Industrial automation is the use of technologies such as computer software and robotics to control machinery and processes which replace human beings in performing specific functions. The functions are primarily centered on manufacturing, quality control and material handling processes.

- Fixed Automation:

- Fixed automation systems are utilized in high volume production settings that have dedicated equipment. The equipment has fixed operation sets and is designed to perform efficiently with the operation sets. This type of automation is mainly used in discrete mass production and continuous flow systems like paint shops, distillation processes, transfer lines and conveyors. All these processes rely on mechanized machinery to perform their fixed and repetitive operations to achieve high production volumes.

- Programmable Automation:

- Programmable automation systems facilitate changeable operation sequences and machine configuration using electronic controls. With programmable automation, non-trivial programming efforts are required to reprogram sequence and machine operations. Since production processes are not changed often, programmable automation systems tend to be less expensive in the long run. This type of system is mainly used in low job variety and medium-to-high product volume settings. It may also be used in mass production settings like paper mills and steel rolling mills.

- Flexible Automation:

- Flexible automation systems are utilized in computer-controlled flexible manufacturing systems. Human operators enter high-level commands in the form of computer codes that identify products and their location in the system’s sequence to trigger automatic lower-level changes. Every production machine receives instructions from a human-operated computer. The instructions trigger the loading and unloading of necessary tools before carrying out their computer-instructed processes. Once processing is completed, the end products are transferred to the next machine automatically. Flexible industrial automation is used in batch processes and job shops with high product varieties and low-to-medium job volumes.

- Integrated Automation:

- Integrated industrial automation involves the total automation of manufacturing plants where all processes function under digital information processing coordination and computer control. It comprises technologies like:

- Computer-aided process planning

- Computer-supported design and manufacturing

- Flexible machine systems

- Computer numerical control machine tools

- Automated material handling systems, like robots

- Automatic storage and retrieval systems

- Computerized production and scheduling control

- Automated conveyors and cranes

- Additionally, an integrated automation system can integrate a business system via a common database. That is, it supports the full integration of management operations and processes using communication and information technologies. Such technologies are utilized in computer integrated manufacturing and advanced process automation systems.

- Integrated industrial automation involves the total automation of manufacturing plants where all processes function under digital information processing coordination and computer control. It comprises technologies like:

- Fixed Automation:

- Industrial automation is the use of technologies such as computer software and robotics to control machinery and processes which replace human beings in performing specific functions. The functions are primarily centered on manufacturing, quality control and material handling processes.

- Process Automation / Manufacturing:

- Process automation is defined as the use of software and technologies to automate business processes and functions in order to accomplish defined organizational goals, such as producing a product, hiring and onboarding an employee, or providing customer service.

- Process manufacturing utilizes chemical, physical and compositional changes to convert raw material or feedstock into a product. Process manufacturing includes industries such as cement and glass, chemicals, electric power generation, food and beverage, life sciences, metals and mining, oil and gas, pulp and paper, refining, and water and wastewater. Process manufacturing includes both continuous and batch processes.

- Discrete Automation / Manufacturing:

- Discrete automation is the production of parts that are of a quantifiable nature. That may include cell phones, soda bottles, automobiles, airplanes, toys, etc. As you know, an automobile contains many, many parts. The parts required for an automobile are also quantifiable in nature.

- Discrete manufacturing processes include the production of individual parts as well as their assembly into a final product. Discrete manufacturing examples include automobiles, appliances, and consumer electronics.

- Hybrid Automation / Manufacturing:

- The Hybrid Automation Method follows two guiding principles: Implementing robust automation solutions that are easy and affordable for organisations to maintain. Realising process efficiency rapidly by reducing project overheads and time-to-value.

- Hybrid manufacturing is a combination of additive manufacturing (AM) and subtractive manufacturing within the same machine.

- Additive Manufacturing (AM):

- Additive manufacturing is the process of creating an object by building it one layer at a time. It is the opposite of subtractive manufacturing, in which an object is created by cutting away at a solid block of material until the final product is complete.

- Operators across a variety of different manufacturing industries utilize additive manufacturing in various ways. For instance: Medical device manufacturers use 3D printing to develop high variance products such as dental implants.

- The term “additive manufacturing” refers to the creation of objects by “adding” material. Therefore, 3D printing is a form of additive manufacturing. When an object is created by adding material — as opposed to removing material — it’s considered additive manufacturing.

- Smart Manufacturing (SM):

- Technology-driven approach that utilizes Internet-connected machinery to monitor the production process. The goal of SM is to identify opportunities for automating operations and use data analytics to improve manufacturing performance.

- An example of what the cloud can do for smart manufacturing is the Volkswagen Industrial Cloud, which combines all data from 122 Volkswagen Group facilities and processes it in real time to make improvements.

- Catalyst Manufacturing:

- Catalyst manufacturing involves the production of substances that accelerate chemical reactions without being consumed themselves. This process often requires specialized equipment and techniques to ensure the catalyst’s desired properties and performance. Key steps in catalyst manufacturing include preparation and mixing of solutions, crystallization, filtration, washing, and calcination.

- Top Catalyst Solutions Companies are M Chemical Company, Inc, Research Catalysts, Inc, Arkema, DuPont, Exxon Mobil Corporation, Johnson Matthey, W. R. Grace & Co …

- Earning Per Share (EPS):

- Company’s net income subtracted by preferred dividends and then divided by the average number of common shares outstanding. The resulting number serves as an indicator of a company’s profitability. It is common for a company to report EPS that is adjusted for extraordinary items and potential share dilution.

- The higher a company’s EPS, the more profitable it is considered to be.

- Earnings per share value is calculated as net income (also known as profits or earnings) divided by available shares. A more refined calculation adjusts the numerator and denominator for shares that could be created through options, convertible debt, or warrants. The numerator of the equation is also more relevant if it is adjusted for continuing operations.

- EBITA:

- Earnings before interest, taxes, and amortization (EBITA) is a measure of company profitability used by investors. It is helpful for comparing one company to another in the same line of business.

- EBITA = Net income + Interest + Taxes + Amortization

- EBITDA:

- Earnings before interest, taxes, depreciation, and amortization (EBITDA) is an alternate measure of profitability to net income. By including depreciation and amortization as well as taxes and debt payment costs, EBITDA attempts to represent the cash profit generated by the company’s operations.

- EBITDA and EBITA are both measures of profitability. The difference is that EBITDA also excludes depreciation.

- EBITDA is the more commonly used measure because it adds depreciation—the accounting practice of recording the reduced value of a company’s tangible assets over time—to the list of factors.

- EV/EBITDA (Enterprise Multiple):

- Enterprise multiple, also known as the EV-to-EBITDA multiple, is a ratio used to determine the value of a company.

- It is computed by dividing enterprise value by EBITDA.

- The enterprise multiple takes into account a company’s debt and cash levels in addition to its stock price and relates that value to the firm’s cash profitability.

- Enterprise multiples can vary depending on the industry.

- Higher enterprise multiples are expected in high-growth industries and lower multiples in industries with slow growth.

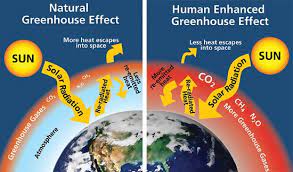

- Global Warming:

- Global warming is the long-term heating of Earth’s climate system observed since the pre-industrial period (between 1850 and 1900) due to human activities, primarily fossil fuel burning, which increases heat-trapping greenhouse gas levels in Earth’s atmosphere.

- Global Warming Potential (GWP):

- The heat absorbed by any greenhouse gas in the atmosphere, as a multiple of the heat that would be absorbed by the same mass of carbon dioxide (CO2). GWP is 1 for CO2. For other gases it depends on the gas and the time frame.

- Carbon dioxide equivalent (CO2e or CO2eq or CO2-e) is calculated from GWP. For any gas, it is the mass of CO2 which would warm the earth as much as the mass of that gas. Thus it provides a common scale for measuring the climate effects of different gases. It is calculated as GWP times mass of the other gas. For example, if a gas has GWP of 100, two tonnes of the gas have CO2e of 200 tonnes.

- GWP was developed to allow comparisons of the global warming impacts of different gases.

- Greenhouse Gas (GHG):

- A greenhouse gas is any gaseous compound in the atmosphere that is capable of absorbing infrared radiation, thereby trapping and holding heat in the atmosphere. By increasing the heat in the atmosphere, greenhouse gases are responsible for the greenhouse effect, which ultimately leads to global warming.

- The main gases responsible for the greenhouse effect include carbon dioxide, methane, nitrous oxide, and water vapor (which all occur naturally), and fluorinated gases (which are synthetic).

- GHG Protocol Corporate Standard Scope 1, 2 and 3: https://ghgprotocol.org/ + The GHG Protocol Corporate Accounting and Reporting Standard provides requirements and guidance for companies and other organizations preparing a corporate-level GHG emissions inventory. Scope 1 and 2 are mandatory to report, whereas scope 3 is voluntary and the hardest to monitor.

- Scope 1: Direct emissions:

- Direct emissions from company-owned and controlled resources. In other words, emissions are released into the atmosphere as a direct result of a set of activities, at a firm level. It is divided into four categories:

- Stationary combustion (e.g fuels, heating sources). All fuels that produce GHG emissions must be included in scope 1.

- Mobile combustion is all vehicles owned or controlled by a firm, burning fuel (e.g. cars, vans, trucks). The increasing use of “electric” vehicles (EVs), means that some of the organisation fleets could fall into Scope 2 emissions.

- Fugitive emissions are leaks from greenhouse gases (e.g. refrigeration, air conditioning units). It is important to note that refrigerant gases are a thousand times more dangerous than CO2 emissions. Companies are encouraged to report these emissions.

- Process emissions are released during industrial processes, and on-site manufacturing (e.g. production of CO2 during cement manufacturing, factory fumes, chemicals).

- Direct emissions from company-owned and controlled resources. In other words, emissions are released into the atmosphere as a direct result of a set of activities, at a firm level. It is divided into four categories:

- Scope 2: Indirect emissions – owned:

- Indirect emissions from the generation of purchased energy, from a utility provider. In other words, all GHG emissions released in the atmosphere, from the consumption of purchased electricity, steam, heat and cooling. For most organisations, electricity will be the unique source of scope 2 emissions. Simply stated, the energy consumed falls into two scopes: Scope 2 covers the electricity consumed by the end-user. Scope 3 covers the energy used by the utilities during transmission and distribution (T&D losses).

- Scope 3: Indirect emissions – not owned:

- Indirect emissions – not included in scope 2 – that occur in the value chain of the reporting company, including both upstream and downstream emissions. In other words, emissions are linked to the company’s operations. According to GHG protocol, scope 3 emissions are separated into 15 categories.

- Scope 1: Direct emissions:

- Biomass:

- Biomass is renewable organic material that comes from plants and animals. Biomass contains stored chemical energy from the sun that is produced by plants through photosynthesis.

- Biomass is a clean, renewable energy source. Its initial energy comes from the sun, and plants or algae biomass can regrow in a relatively short amount of time. Trees, crops, and municipal solid waste are consistently available and can be managed sustainably.

- Bioenergy:

- It is a form of renewable energy that is derived from recently living organic materials known as biomass, which can be used to produce transportation fuels, heat, electricity, and products.

- Bioenergy is renewable energy produced from organic matter (called “biomass”) such as plants, which contain energy from sunlight stored as chemical energy. Bioenergy producers can convert this energy into liquid transportation fuel—called “biofuel”—through a chemical conversion process at a biorefinery.

- Types of bioenergy include biogas, bioethanol, and biodiesel which may be sourced from plants (corn, sugarcane), wood, agricultural wastes, and bagasse. Bioenergy is considered renewable because its source is inexhaustible, as plants obtain their energy from the sun through photosynthesis which can be replenished.

- Biofuel:

- Any fuel that is derived from biomass—that is, plant or algae material or animal waste. Since such feedstock material can be replenished readily, biofuel is considered to be a source of renewable energy, unlike fossil fuels such as petroleum, coal, and natural gas.

- The two most common types of biofuels in use today are ethanol and biodiesel, both of which represent the first generation of biofuel technology.

- e-Fuels – Electrofuels:

- eFuels are produced with electricity from renewable sources, water and CO2 and are a sustainable alternative to fossil fuels.

- Electrofuels, also known as e-fuels or synthetic fuels, are a type of drop-in replacement fuel. They are manufactured using captured carbon dioxide or carbon monoxide, together with hydrogen obtained from sustainable electricity sources such as wind, solar and nuclear power.

- e-Methanol:

- eMethanol is also referred to as ‘green’ methanol because of the way in which it is produced: combining biogenic CO2 (put simply, CO2 created by burning biologically based materials, such as biomass) with hydrogen, created by water electrolysis.

- E-methanol is produced by combining green hydrogen and captured carbon dioxide from industrial sources. It still releases some greenhouse gases as it burns, but it emits less carbon dioxide, nitrogen oxides, sulfur oxide and particulate matter than conventional marine fuel.

- Methanol – CH3OH – is four parts hydrogen, one part oxygen and one part carbon. On an industrial scale, methanol is predominantly produced from natural gas by reforming the gas with steam and then converting and distilling the resulting synthesized gas mixture to create pure methanol.

- SAF (Sustainable Aviation Fuel):

- SAF stands for sustainable aviation fuel. It’s produced from sustainable feedstocks and is very similar in its chemistry to traditional fossil jet fuel. Using SAF results in a reduction in carbon emissions compared to the traditional jet fuel it replaces over the lifecycle of the fuel.

- SAF is made by blending conventional kerosene (fossil-based) with renewable hydrocarbon. They are certified as “Jet-A1” fuel and can be used without any technical modifications to aircraft.

- SAF prices are currently about five times higher than prices for conventional jet fuel, data on European spot market prices collected by OPIS show. OPIS is an IHS Markit unit. The disruption to the aviation industry as a result of the COVID-19 pandemic makes cost issues even more prominent today.

- Hydrogen:

- The atom of hydrogen is the first element in the periodic table, with chemical symbol H and the first element created after the Big Bang. It is the most common substance in the universe and the richest energy source for stars like the sun. It consists of one proton (a core unit of positive charge) and one electron (negative charge).

- Hydrogen doesn’t exist naturally on Earth. Since it forms covalent compounds with most non-metallic elements, most of the hydrogen on Earth exists in molecular forms such as water or organic compounds. Combined with oxygen, it is water (H2O). Combined with carbon, it forms methane (CH4), coal, and petroleum. It is found in all growing things (biomass).

- Hydrogen (H2) is the most abundant element on earth but it rarely exists alone, therefore it is produced by extracting it from its compound.

- Hydrogen can be produced in numerous ways. Some methods produce CO2 while others are carbon free.

- H2 can be renewable or decarbonized if produced using renewable or carbon free electricity.

- Hydrogen has the highest energy content of any common fuel by weight.

- Hydrogen is a high efficiency, low polluting fuel that can be used for transportation, heating, and power generation in places where it is difficult to use electricity or as a CO2 neutral feedstock for chemical processes (ammonia-fertilizers).

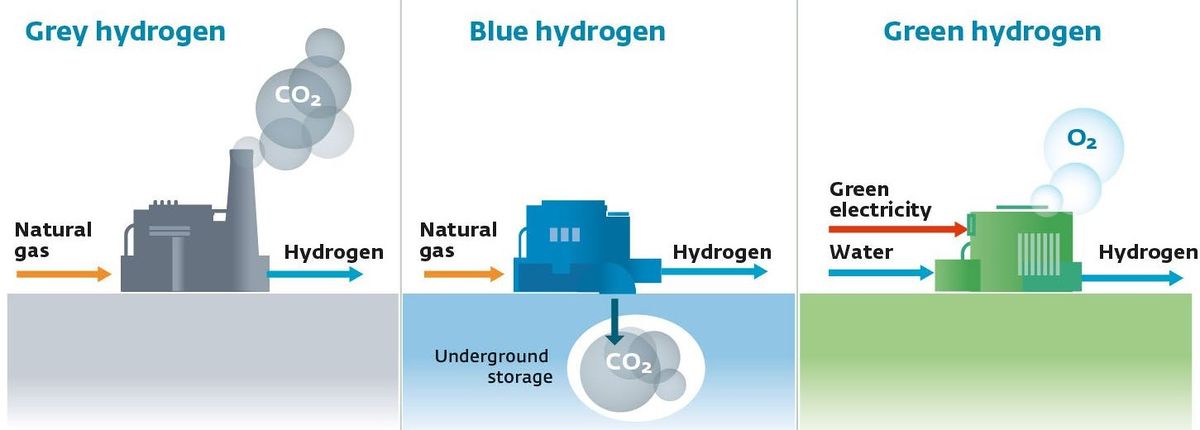

- Grey, Blue or Green Hydrogen:

- There is a growing international consensus that clean hydrogen will play a key role in the world’s transition to a sustainable energy future. It is crucial to help reduce carbon emissions from industry and heavy transport, and also to provide long-term energy storage at scale.

- Researchers have found that clean hydrogen still costs too much to enable it to be widely deployed. Prices may not come down sufficiently until the 2030s, according to some estimates. But despite the uncertainty surrounding the future of clean hydrogen, there are promising signs that it could become more affordable sooner than expected.

- Where the hydrogen comes from is important. At the moment, it’s mainly produced industrially from natural gas, which generates significant carbon emissions. That type is known as “grey” hydrogen.

- A cleaner version is “blue” hydrogen, for which the carbon emissions are captured and stored, or reused.

- The cleanest one of all is “green” hydrogen, which is generated by renewable energy sources without producing carbon emissions in the first place.

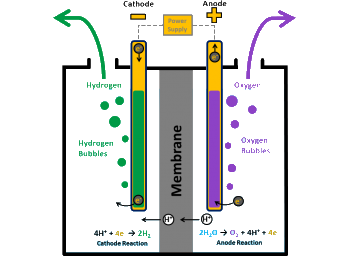

- Hydrogen Electrolyzer:

- An electrolyzer is a system that uses electricity to break water into hydrogen and oxygen in a process called electrolysis. Through electrolysis, the electrolyzer system creates hydrogen gas.

- Steam at the cathode combines with electrons from the external circuit to form hydrogen gas and negatively charged oxygen ions. The oxygen ions pass through the solid ceramic membrane and react at the anode to form oxygen gas and generate electrons for the external circuit.

- Ammonia (Ammonia as fuel):

- Ammonia is a colorless highly irritating gas with a sharp suffocating odor. It dissolves easily in water to form ammonium hydroxide solution which can cause irritation and burns. Ammonia gas is easily compressed and forms a clear, colorless liquid under pressure.

- Ammonia burns slower and is harder to ignite than fossil fuels; most ammonia engines need a dose of diesel or hydrogen to get them going. If engines leak unburned ammonia, that can be toxic. And ammonia engines tend to produce nitrogen oxide, also a potent greenhouse gas.

- Ammonia has a higher energy density, at 12.7 MJ/L, than even liquid hydrogen, at 8.5 MJ/L. Liquid hydrogen has to be stored at cryogenic conditions of –253 °C, whereas ammonia can be stored at a much less energy-intensive –33 °C. And ammonia, though hazardous to handle, is much less flammable than hydrogen.

- e-Ammonia:

- E-ammonia is made from three simple inputs: water, air, and renewable electricity. First, hydrogen is generated from water using electrolysis (e-hydrogen) and nitrogen is separated from air. Second, these feedstocks of hydrogen and nitrogen are combined in the century-old Haber-Bosch synthesis process to make ammonia.

- Green ammonia is indistinguishable from (grey) ammonia: the only difference is the carbon emissions, as green H2 from renewable electricity is used instead of grey H2 from fossil fuel (natural gas).

- Hydrocarbon:

- A hydrocarbon is any of a class of organic chemicals made up of only the elements carbon (C) and hydrogen (H). The carbon atoms join together to form the framework of the compound, and the hydrogen atoms attach to them in many different configurations.

- Feedstock:

- Feedstock refers to the raw material that is required for some industrial process. Examples of feedstock include crude oil, which is used to produce gasoline, corn, which is used to produce ethanol, and soybean oil, which is used to produce biodiesel.