NKT – NKT signs EUR 1 billion supply agreement with Hydro for low-carbon aluminium wire rod through to 2033

The agreement will ensure security of supply of a critical raw material from a European partner, support NKT’s decarbonisation journey and enhance the sustainability of medium- and high-voltage power cable solutions.

NKT has signed a landmark supply agreement with Hydro to secure a long-term supply of low-carbon aluminium wire rod through to 2033, with an estimated contract value of approximately EUR 1 billion, depending on the quantity, duration options and future metal prices.This agreement plays a crucial role in NKT’s ongoing decarbonisation efforts, enabling the company to deliver power cable solutions with a significantly lower carbon footprint to its customers.

– This long-term supply agreement with Hydro not only guarantees a long-term, European supply of low-carbon aluminium, it also reinforces our position as a sustainability leader in the power cable industry. It supports our strategy to continuously improve the carbon intensity of our power cables thereby supporting both our own short and long-term targets and our customers’ decarbonisation ambitions. Given the current geopolitical landscape, securing reliable, local supply chains is increasingly important, says Claes Westerlind, CEO and President of NKT.

Both NKT and Hydro recognise the importance of decarbonising the aluminium and power cable supply chains in order to ensure a sustainable future. With this agreement, NKT is well-positioned to meet the robust market demand for its medium- and high-voltage power cable solutions, while strengthening Europe’s ability to build out a clean and secure power grid through a locally sourced supply chain.

– It is with a sense of urgency that Europe is now mobilising to reduce the dependency on fossil fuel imports, introduce more homegrown, renewable power, and ensure security of supply of critical raw materials. Together with NKT, we are building a supply chain to provide responsibly sourced aluminium for the infrastructure makeover that Europe needs to bring down energy prices, accelerate the energy transition, and boost European competitiveness, says Eivind Kallevik, President and CEO of Hydro.

Reliable, low-carbon supply chain for the future

The agreement ensures that NKT will have access to Hydro’s REDUXA 4.01, the world’s lowest-carbon EC grade aluminium wire rod. Hydro aims to reduce the carbon footprint by a further 25% by 2030, with NKT having first rights to Hydro’s REDUXA 3.0 aluminium.

Aluminium is a critical component in medium- and high-voltage power cables, which are essential for Europe’s ongoing energy transition. As society continues to electrify and renewable energy sources become more prevalent, power grids across Europe are undergoing significant upgrades.

To meet NKT’s growing demand, Hydro recently announced a EUR 140 million investment in a new, state-of-the-art casthouse. This investment ensures a reliable, local, and sustainable supply chain, while also mitigating risks associated with regulatory and geopolitical shifts.

Key facts:

- Contract duration: 2025-2033

- Contract value: Estimated contract value of approximately EUR 1 billion depending on quantity, duration options and future metal prices

- Product impact: The majority of the low-carbon aluminium will go to medium-voltage sites in Falun, Sweden, and Asnaes, Denmark.

- Several high-voltage cable system projects, including 525 kV XLPE HVDC power cables, produced in Karlskrona, Sweden, will also receive low-carbon aluminium from Hydro under the supply agreement.

- The contract includes a joint decarbonisation roadmap

- NKT and Hydro have been partners for more than 40 years

1 – REDUXA 4.0 has a carbon footprint below 4.0 kg CO2e per kg aluminum, which is one-fourth the global average

SourceNKT

EMR Analysis

More information on NKT: See the full profile on EMR Executive Services

More information on Claes Westerlind (President and Chief Executive Officer, NKT): See the full profile on EMR Executive Services

More information on Hydro: https://www.hydro.com/en/ + Since 1905, Hydro has turned natural resources into valuable products for people and businesses, creating a safe and secure workplace for our 32,000 employees in more than 140 locations and 42 countries.

Today, we own and operate various businesses and have investments with a base in sustainable industries. Hydro is through its businesses present in a broad range of market segments for aluminium, energy, metal recycling, renewables and batteries, offering a unique wealth of knowledge and competence.

- 2024 Revenue: NOK 203,636 million

- Adjusted EBITDA: NOK 26,318 million

- Net income from continuing operations: NOK 5,040 million

More information on Eivind Kallevik (President and Chief Executive Officer, Hydro): https://www.hydro.com/en/global/about-hydro/management-and-organization/corporate-management/ + https://www.linkedin.com/in/eivindkallevik/

EMR Additional Notes:

- Carbon Dioxide (CO2):

- Primary greenhouse gas emitted through human activities. Carbon dioxide enters the atmosphere through burning fossil fuels (coal, natural gas, and oil), solid waste, trees and other biological materials, and also as a result of certain chemical reactions (e.g., manufacture of cement). Carbon dioxide is removed from the atmosphere (or “sequestered”) when it is absorbed by plants as part of the biological carbon cycle.

- Biogenic Carbon Dioxide (CO2):

- Biogenic Carbon Dioxide (CO2) and Carbon Dioxide (CO2) are the same. Scientists differentiate between biogenic carbon (that which is absorbed, stored and emitted by organic matter like soil, trees, plants and grasses) and non-biogenic carbon (that found in all other sources, most notably in fossil fuels like oil, coal and gas).

- Decarbonization:

- Reduction of carbon dioxide emissions through the use of low carbon power sources, achieving a lower output of greenhouse gasses into the atmosphere.

- Carbon Footprint:

- There is no universally agreed definition of what a carbon footprint is.

- A carbon footprint is generally understood to be the total amount of greenhouse gas (GHG) emissions that are directly or indirectly caused by an individual, organization, product, or service. These emissions are typically measured in tonnes of carbon dioxide equivalent (CO2e).

- In 2009, the Greenhouse Gas Protocol (GHG Protocol) published a standard for calculating and reporting corporate carbon footprints. This standard is widely accepted by businesses and other organizations around the world. The GHG Protocol defines a carbon footprint as “the total set of greenhouse gas emissions caused by an organization, directly and indirectly, through its own operations and the value chain.”

- CO2e (Carbon Dioxide Equivalent):

- CO2e means “carbon dioxide equivalent”. In layman’s terms, CO2e is a measurement of the total greenhouse gases emitted, expressed in terms of the equivalent measurement of carbon dioxide. On the other hand, CO2 only measures carbon emissions and does not account for any other greenhouse gases.

- A carbon dioxide equivalent or CO2 equivalent, abbreviated as CO2-eq is a metric measure used to compare the emissions from various greenhouse gases on the basis of their global-warming potential (GWP), by converting amounts of other gases to the equivalent amount of carbon dioxide with the same global warming potential.

- Carbon dioxide equivalents are commonly expressed as million metric tonnes of carbon dioxide equivalents, abbreviated as MMTCDE.

- The carbon dioxide equivalent for a gas is derived by multiplying the tonnes of the gas by the associated GWP: MMTCDE = (million metric tonnes of a gas) * (GWP of the gas).

- For example, the GWP for methane is 25 and for nitrous oxide 298. This means that emissions of 1 million metric tonnes of methane and nitrous oxide respectively is equivalent to emissions of 25 and 298 million metric tonnes of carbon dioxide.

- Carbon Capture and Storage (CCS) – Carbon Capture, Utilisation and Storage (CCUS):

- CCS involves the capture of carbon dioxide (CO2) emissions from industrial processes. This carbon is then transported from where it was produced, via ship or in a pipeline, and stored deep underground in geological formations.

- CCS projects typically target 90 percent efficiency, meaning that 90 percent of the carbon dioxide from the power plant will be captured and stored.

- Carbon Dioxide Removal (CDR):

- Carbon Dioxide Removal encompasses approaches and methods for removing CO2 from the atmosphere and then storing it permanently in underground geological formations, in biomass, oceanic reservoirs or long-lived products in order to achieve negative emissions.

- Direct Air Capture (DAC):

- Technologies extracting CO2 directly from the atmosphere at any location, unlike carbon capture which is generally carried out at the point of emissions, such as a steel plant.

- Constraints like costs and energy requirements as well as the potential for pollution make DAC a less desirable option for CO2 reduction. Its larger land footprint when compared to other mitigation strategies like carbon capture and storage systems (CCS) also put it at a disadvantage.

- Carbon Credits or Carbon Offsets:

- Permits that allow the owner to emit a certain amount of carbon dioxide or other greenhouse gases. One credit permits the emission of one ton of carbon dioxide or the equivalent in other greenhouse gases.

- The carbon credit is half of a so-called cap-and-trade program. Companies that pollute are awarded credits that allow them to continue to pollute up to a certain limit, which is reduced periodically. Meanwhile, the company may sell any unneeded credits to another company that needs them. Private companies are thus doubly incentivized to reduce greenhouse emissions. First, they must spend money on extra credits if their emissions exceed the cap. Second, they can make money by reducing their emissions and selling their excess allowances.

- Wire Rod:

- Wire rod is a rolled steel product (alloy or non-alloy), manufactured from semi-finished steel with a rectangular, rounded, hexagonal or squared shape. Especially, fine cross-sections are reached by sequent cold drawing. Wire rod is wrapped around into the coils and also carried in this form.

- The key difference between a wire and a rod is that a wire can be bent, stretch, or can be coiled into any shape without breaking. Where as a rod is a robust, thick, generally having circular cross section thing and which cannot be bent or coiled into any shape at room temperature.

- Extra Low-Voltage (ELV):

- Voltage of 50V or less (AC RMS), or 120V or less (ripple-free DC).

- Low-Voltage (LV):

- The International Electrotechnical Commission (IEC) defines supply system low voltage as voltage in the range 50–1000 V AC or 120–1500 V DC.

- Medium-Voltage (MV):

- Medium-voltage circuit breakers rated between 1 and 35/72 kV.

- High-Voltage (HV):

- The International Electrotechnical Commission define high voltage as above 1000 V for alternating current, and at least 1500 V for direct current.

- Super High-Voltage or Extra High-Voltage (EHV):

- Is >300kV.

- Ultra High-Voltage (UHV):

- Is >1.000kV.

- Power Cable:

- A high-voltage cable (HV cable), sometimes called a high-tension cable (HT cable), is a cable used for electric power transmission at high voltage. A cable includes a conductor and insulation. Cables are considered to be fully insulated.

- The main difference between hv and lv cables is that high-voltage cables have more semiconductor layers and shielding layers than low-voltage cables. Therefore, high-voltage cables than low-voltage cable insulation layers are much thicker, and the structure is more complex, the process requirements are also high.

- Grid, Microgrids, DERs and DERM’s:

- The power grid is a network for delivering electricity to consumers. The power grid includes generator stations, transmission lines and towers, and individual consumer distribution lines.

- The grid constantly balances the supply and demand for the energy that powers everything from industry to household appliances.

- Electric grids perform three major functions: power generation, transmission, and distribution.

- A microgrid is a small-scale power grid that can operate independently or collaboratively with other small power grids. The practice of using microgrids is known as distributed, dispersed, decentralized, district or embedded energy production.

- Smart Grid is any electrical grid + IT at all levels . Micro Grid is a group of interconnected loads and DERs (Distributed energy resources) within a clearly defined electrical and geographical boundaries witch acts as a single controllable entity with respect to the main grid.

- Distributed energy resources (DERs) are small-scale electricity supply (typically in the range of 3 kW to 50 MW) or demand resources that are interconnected to the electric grid. They are power generation resources and are usually located close to load centers, and can be used individually or in aggregate to provide value to the grid.

- Common examples of DERs include rooftop solar PV units, natural gas turbines, microturbines, wind turbines, biomass generators, fuel cells, tri-generation units, battery storage, electric vehicles (EV) and EV chargers, and demand response applications.

- Distributed energy resources management systems (DERMS) are platforms which helps mostly distribution system operators (DSO) manage their grids that are mainly based on distributed energy resources (DER).

- DERMS are used by utilities and other energy companies to aggregate a large energy load for participation in the demand response market. DERMS can be defined in many ways, depending on the use case and underlying energy asset.

- Supply Chain:

- Network of all the individuals, organizations, resources, activities and technology involved in the creation and sale of a product. A supply chain encompasses everything from the delivery of source materials from the supplier to the manufacturer through to its eventual delivery to the end user.

- At the most fundamental level, supply chain management (SCM) is management of the flow of goods, data, and finances related to a product or service, from the procurement of raw materials to the delivery of the product at its final destination.

- EC Grade Aluminium:

- Electrical Conductor grade, is a type of aluminum characterized by its high purity (typically 99.5% or higher) and excellent electrical conductivity. This makes it ideal for applications in the electrical industry, particularly for manufacturing wires, cables, and other conductive components.

- Metallurgical composition of aluminum with maximum percentage content as follows: Si-0.10, Fe-0.4, Cu-0.05, Mn-0.01, Cr 0.01, Zn-0.05, B-0.05, Ga-0.03; vanadium plus titanium, total, max.-0.02; other elements, each, max.-0.03; other elements, total, max.-0.10. Minimum aluminum content 99.5 percent.

- Casthouse:

- A casthouse, in the context of the metallurgical industry, is the area where molten metal, typically aluminum, iron, or other metals, is processed and transformed into various finished or semi-finished products. This involves controlling the molten metal’s temperature and composition, adding alloys, and pouring it into molds or casting machines to create solid forms like billets, ingots, or other shapes.

- XLPE:

- Cross-linked polyethylene, commonly abbreviated PEX, XPE or XLPE, is a form of polyethylene with cross-links.

- XLPE or Cross-linked polyethylene is a thermoset insulation material. Crosslinking polymers is a process which changes the molecular structure of the polymer chains so that they are more tightly bound together and this crosslinking is done either by chemical means or physical means.

- XLPE is suitable for voltage ranges from low to extra high voltage, surpassing other insulation materials such as PVC, Ethylene Propylene Rubber (EPR) and silicone rubbers. Cross-linking the polyethylene also enhances the chemical and oil resistance at elevated temperatures and makes it suitable for use as a Low Smoke Zero Halogen material.

- HVDC Light:

- HVDC Light is the successful and environmentally-friendly way to design a power transmission system for a submarine cable, an underground cable, using over head lines or as a back-to-back transmission. HVDC Light is HVDC technology based on voltage source converters (VSCs).

- HVDC Light is designed to transmit power underground and underwater, also over long distances. It offers numerous environmental benefits, including “invisible” power lines, neutral electromagnetic fields, oil-free cables and compact converter stations.

- As its name implies, HVDC Light is a dc transmission technology. However, it is different from the classic HVDC technology used in a large number of transmission schemes. Classic HVDC technology is mostly used for large point-to-point transmissions, often over vast distances across land or under water. It requires fast communications channels between the two stations, and there must be large rotating units – generators or synchronous condensers – present in the AC networks at both ends of the transmission. HVDC Light consists of only two elements: a converter station and a pair of ground cables. The converters are voltage source converters, VSC’s. The output from the VSC’s is determined by the control system, which does not require any communications links between the different converter stations. Also, they don’t need to rely on the AC network’s ability to keep the voltage and frequency stable. These feature make it possible to connect the converters to the points bests suited for the AC system as a whole.

- HVDC (High-Voltage Direct Current):

- Key enabler for a carbon-neutral energy system. It is highly efficient for transmitting large amounts of electricity over long distances, integration of renewables and interconnecting grids, opening up for new sustainable transmission solutions.

- HVDC Links:

- The first successful HVDC experimental long distance line (37 miles) was made at Munich, Germany in 1882 by Oskar Von Miller and fellow engineers.

- HVDC allows power transmission between AC transmission systems that are not synchronized. Since the power flow through an HVDC link can be controlled independently of the phase angle between source and load, it can stabilize a network against disturbances due to rapid changes in power.

- An HVDC line has considerably lower losses compared to HVAC over longer distances.

- Neu Connect (the first power interconnection between Great Britain and Germany): https://neuconnect-interconnector.com +

- The NeuConnect Interconnector will create the first direct power link between Germany and Great Britain, connecting two of Europe’s largest energy markets for the first time. Around 720km of land and subsea cables will form an ‘invisible highway’ allowing up to 1.4GW of electricity to move in either direction, enough to power up to 1.5 million homes over the life of the project.

- The Tyrrhenian Link: https://www.terna.it/en/projects/public-engagement/Tyrrhenian-link +

- Connecting Sicily with Sardinia and the Italian peninsula via a double underwater cable: a new electricity corridor at the centre of the Mediterranean; the Tyrrhenian Link. At 950 kilometres long and with a capacity of 1000 MW, this is an infrastructure initiative of international significance, another step towards a more sustainable energy future. The link will improve electricity exchange capacity, facilitate the development of renewable energy sources, and the reliability of the grid.

- The overall project involves two sections: EAST from Sicily to Campania and WEST from Sicily to Sardinia.

- The East section is 480 kilometres long and connects the Fiumetorto landing point, in the municipality of Termini Imerese in Sicily, with the landing point in Torre Tuscia Magazzeno, near Battipaglia in Campania.

- The WEST section is approximately 470 kilometres long and connects the Fiumetorto landing point to the one in Terra Mala, in Sardinia.

- The Viking Link: https://viking-link.com + World’s longest power interconnection. the Viking Link is a 1400 MW high voltage direct current (DC) electricity link between the British and Danish transmission systems connecting at Bicker Fen substation in Lincolnshire and Revising substation in southern Jutland, Denmark.

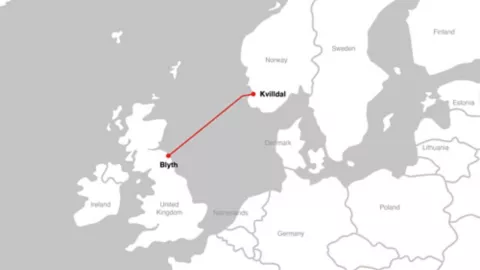

- The North Sea Link: https://northsealink.com/ + North Sea Link is a 720 kilometre subsea interconnector linking the electricity systems of the UK and Norway. The 1400 megawatt interconnector stretches from Blyth in the UK, across the North Sea, to Kvilldal in Norway.

- The Hertel–New York interconnection line: https://www.hydroquebec.com/projects/hertel-new-york-interconnection/ + The Hertel–New York interconnection line project aims to supply clean, renewable energy to New York City. In Québec, the project involves the construction of a line that will span 57.7 km (56.1 km underground and 1.6 km underwater). This 400-kV direct current line will connect Hertel substation in La Prairie to an interconnection point in the Rivière Richelieu at the Canada–United States border.

- The Biscay Gulf Project: https://www.inelfe.eu/en/projects/bay-biscay + The electricity interconnection between Gatika (Spain) and Cubnezais (France) will be the first fundamentally submarine interconnection between Spain and France. This project will increase the exchange capacity from 2,800 to 5,000 MW, improving the safety, stability and quality of electricity supply between the two countries and also with the rest of Europe.

- The Eastern Green Link 2 (EGL2): https://www.ssen-transmission.co.uk/projects/project-map/eastern-green-link-2/ + The Eastern Green Link 2 project is a proposal to install a sub-sea high-voltage direct current (HVDC) cable from Sandford Bay, at Peterhead, to Drax in England. There is currently a large amount of forecasted generation that will require connection to the electricity network in the coming years and as such we are proposing several upgrades to the transmission network across the north of Scotland to facilitate this. The Eastern HVDC Link will play a key role in helping achieve our Net-Zero targets.

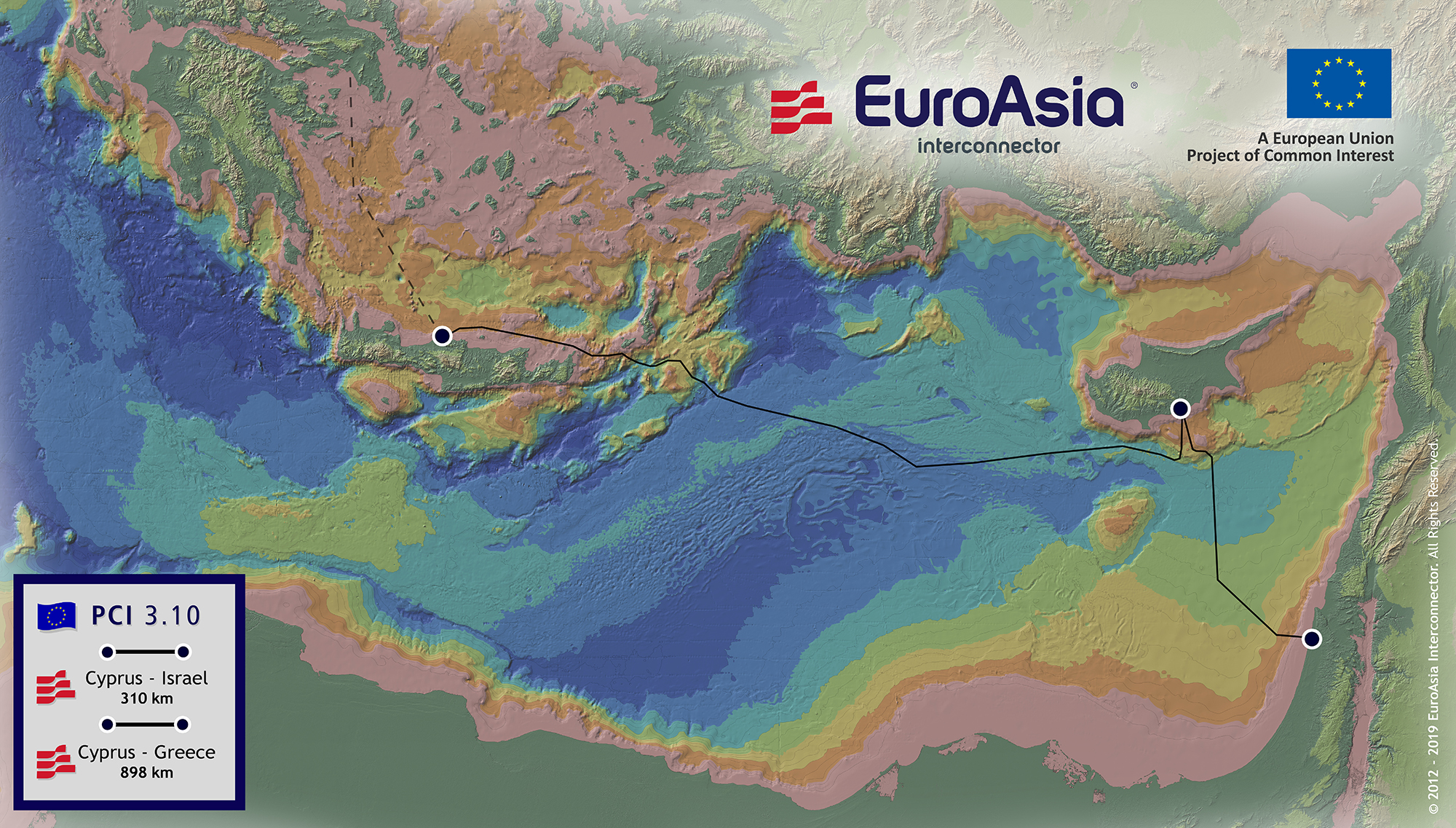

- The EuroAsia Interconnector: https://euroasia-interconnector.com/ + EuroAsia Interconnector Limited is the official EU project developer of the 2,000MW electricity interconnector between Israel, Cyprus, Greece and Europe. The EuroAsia Interconnector is a leading European Project of Common Interest (PCI) labelled as an EU “electricity highway” connecting the national electricity grids of Israel, Cyprus and Greece through a 1,208 km subsea HVDC cable.

- The EuroAsia Interconnector comprises the electricity interconnection between the grids of Israel, Cyprus, Greece through a subsea DC cable and with HVDC onshore converter stations at each connection point, with a total capacity of 2000MW. The project is an energy highway bridging Asia and Europe, with a total length of 1,208 km. It creates a reliable alternative route for the transfer of electric energy to and from Europe.